Sheet Metal Fabrication

If you are looking for a sheet metal fabrication shop, you can trust the Xnparts team to provide you with the services you need. From a single prototype or short run to full-scale manufacturing, we have the custom metal fabrication tools and experience you need to ensure your project is a success.

One-Stop Sheet Metal Fabrication Partner

At Xnparts, we understand the challenges of manufacturing complex sheet metal products and are here to help. The key difference between us and other manufacturing companies is our ability to quote, design, manufacture, assemble and ship your parts all under one roof, one-stop service. Our state-of-the-art facilities, advanced sheet metal fabrication technology and equipment, and skilled engineering and production teams enable us to provide high-quality custom sheet metal components to meet your business needs.

We have a wide range of materials and processes, as well as assembly and support design and quality control capabilities, from design for manufacturability (DFM) to prototyping, to high-quality finished products that can be consistently and efficiently mass-produced in fast turnaround times. Our goal is to be your reliable manufacturing supplier partner, providing reliable, high-quality, on-time production scheduling and delivery services to your supply chain network.

From concept to installation

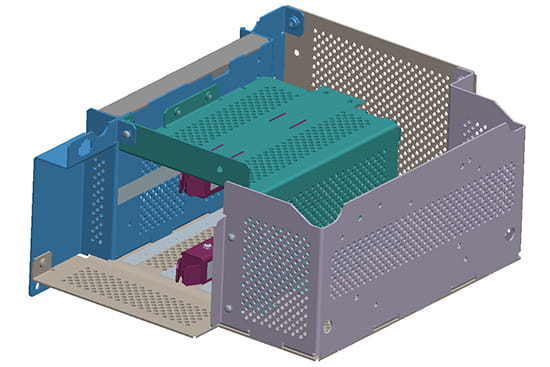

Our sheet metal fabrication shop can assist you with your project from start to finish, or step in when needed. If you need guidance in your project, our team can first design a custom solution based on your needs. Your ideas will be transformed into appropriate CAD drawings or 3D models. The design will then be sent to you for review and approval. Once you sign off, our team will begin manufacturing the perfect product. Once completed, we will ship the product to your location, including all necessary installation instructions. We will even complete the installation for you upon request.

Design for Manufacturing

Before starting a project, we will evaluate your drawings and check if your design is suitable for workshop production:

- Bend radius, bend relief, hole diameter, hole-to-hole distance, hole-to-edge distance, etc.;

- Dimensional and geometric tolerances. They must be achievable and ensure proper operation;

- What kind of problems may occur during the production of such a product.

Detailed Quality Control Report

During the production process or before shipment, we will send you a detailed quality control report, which may include dimensional reports, material certificates, etc. (such as salt spray test reports, etc.). We will also send you pictures and videos so that you can stay updated. When you receive the products, they will be exactly as you expect.

Packaging and loading plan design

Sheet metal parts must be properly packaged to avoid damage during handling and transportation. Otherwise, they can be easily bent, deformed or scratched. For a fully loaded container, we will design the best loading plan to fit more products into the container, which will save transportation costs and keep the items neat and organized during loading.

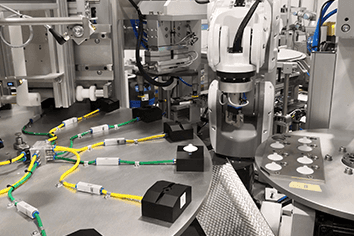

Modern Equipment Required for the Modern World

At Xnparts, we pride ourselves on having cutting-edge equipment that enables us to deliver exceptional results. Our state-of-the-art machines include advanced CNC plasma cutting systems, high-performance press brakes, precision laser cutting machines, and versatile water jet cutting technology. With this modern equipment, we can process a wide range of materials and ensure precise cuts, complex designs, and efficient manufacturing processes. From initial concept to final product, our state-of-the-art equipment enables us to meet the demands of the modern world and exceed our customers’ expectations.

Get in touch with our precision sheet metal fabrication experts

Whether your project has a tight timeline, requires high precision, deals with highly complex parts, or requires low-volume manufacturing, Xnparts can easily meet your needs. Our experts use cutting-edge technology, proven processes, and meticulous attention to detail to ensure your project is completed on time, on budget, and to the highest standards.

Our Sheet Metal Fabrication Capabilities

Xnparts typically uses 4 Sigma quality standards with a tolerance of +/-.006″ / .15mm for standard feature sizes (holes, squares, etc.). For single hit, flat pattern relationships, the tolerance is ‘+/-.010″ / .25mm. Tolerances vary from project to project, and our machining capabilities allow us to meet tighter tolerance requirements, such as military, aerospace, and defense products.

While the maximum part size and thickness may vary depending on the sheet metal used, our accuracy capabilities are the same for all parts. The maximum dimensional accuracy for all sheet metal fabrication parts is ±0.13mm, the minimum complex feature size is 1x1mm, and the minimum laser cut is 0mm. The maximum sheet size is 3000 x 1500mm, and the maximum thickness of any part is 25.4mm.

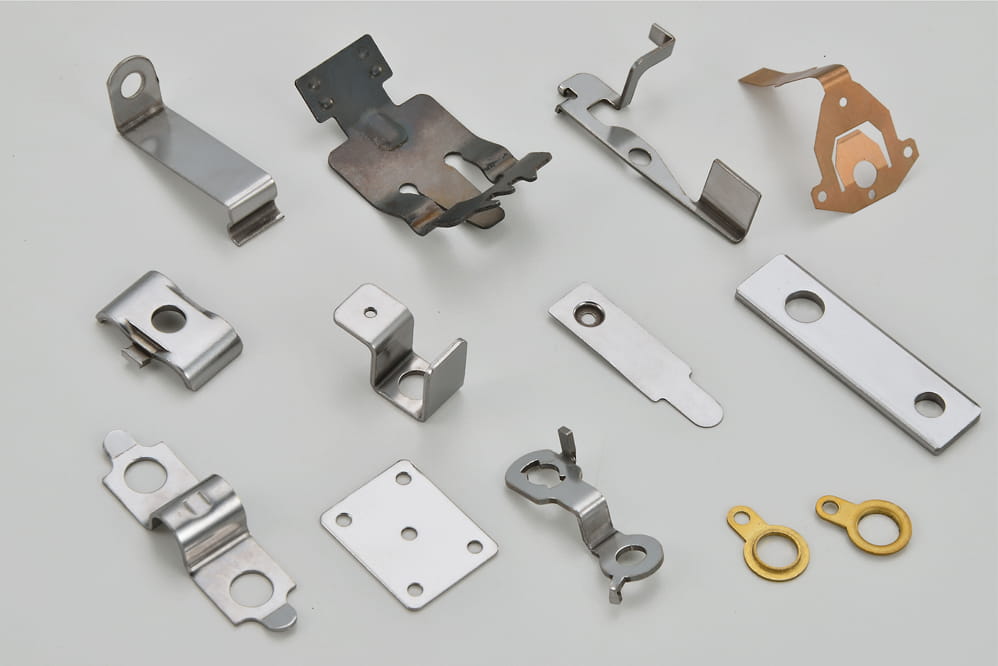

We provide custom sheet metal fabrication services

With extensive fabrication and finishing capabilities, we can handle everything from small batch prototypes to high volume production. Our knowledgeable team of engineers ensures that each sheet metal component is manufactured to precise specifications and quality standards. Whether your project is a single component or multiple assemblies.

Stamping

Bending

Welding

Laser Cutting

Waterjet Cutting

Plasma Cutting

Punching

Riveting

Assembly

Quality Policy

At Xnparts, quality is always the core value of the company. In order to implement this business philosophy, we have developed a comprehensive quality inspection program to ensure that every step of production meets strict standards. The program covers all stages from raw material procurement to final product delivery. When the raw materials are put into storage, we will conduct detailed inspections to ensure that the materials used meet the predetermined requirements.

- Raw material inspection

- Tool detection

- In-production testing

- Pre-packaging inspection

- Pre-shipment inspection

Engineering Design

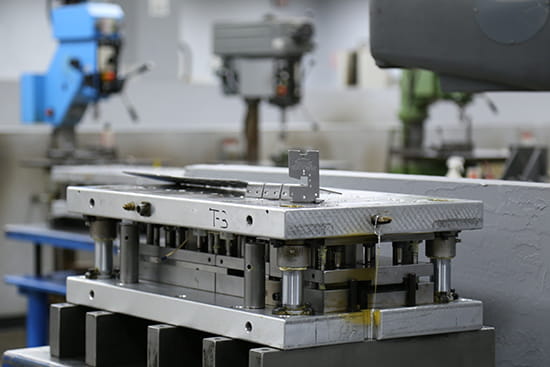

Tool and Die Manufacturing

Internal tool and mold workshop

Xnparts has an internal dedicated tool and mold workshop equipped with advanced CNC equipment, which can flexibly manufacture and modify a variety of tools and molds to meet different production needs. Our CNC technology not only improves production efficiency, but also ensures the accuracy and consistency of tool processing. In addition, we regularly carry out comprehensive care and maintenance of the tools in stock, including cleaning, lubrication and repair when necessary. These measures are designed to ensure that all tools are always in the best condition and put into production at any time, thereby reducing downtime and improving overall production capacity. At the same time, we have also established a detailed record system to track the use and maintenance history of each tool so that potential problems can be discovered in time and corresponding measures can be taken to further improve management level and service quality.

Streamline Your Supply Chain

If you are looking for a sheet metal manufacturer that can handle everything from new product development and prototype parts to high-volume production and assembly services, Xnparts can definitely meet your expectations. Our comprehensive large-scale sheet metal fabrication services can help you streamline your supply chain and accelerate your time to market.

We use a value engineering approach to every project to ensure that your parts can be produced quickly and cost-effectively. Whether your design is simple or complex, our experts will manage every step of the process, from design assistance, rapid prototyping, mass production and assembly.

Sheet Metal Part Materials

Xnparts offers a wide variety of material options for our sheet metal fabrication process. Each material is available in different grades and varieties. If you would like to see a specific material used in your sheet metal fabrication process, please feel free to contact us!

- Carbon Steel

- Stainless Steel

- Aluminum

- Magnesium

- Bronze

- Galvanized Steel

- Copper/Brass/Bronze

- Alloy Steel

- Engineering Plastics

Available Finish Options

We offer a variety of custom finishes to suit all of our products for added protection, durability, aesthetics and artistry.

- Anodic oxidation

- Galvanized

- Black oxide coating

- Chrome plating

- Electroplating

- Laser Marking

- Mirror polishing

- Wire drawing

- Powder coating

- Sandblasting

- Laser engraving

- Printing

What is Sheet Metal Fabrication?

Sheet metal fabrication is essentially the process of manufacturing metal parts and products made from raw sheet metal. It is a manufacturing process that converts sheet metal into custom functional parts. The process typically involves removing material from the sheet to form a basic shape, and then may involve secondary steps such as bending to create more complex 3D shapes. Sheet metal fabrication processes typically involve CNC (Computer Numerical Control) machines that automatically guide the cutting or manual forming process under computer control. The fabrication process produces precision parts with simple or complex shapes through automated cutting processes and manual processes.

Advantages

- Affordable: Sheet metal fabrication is less expensive than machining and offers a great deal of flexibility in every step of the manufacturing process.

- Precise: Metal parts can be cut to precise sizes and shapes using computer-controlled equipment. This minimizes the need for secondary operations such as grinding and polishing.

- Scalability: Sheet metal forming can easily adapt to production changes without a large investment in retooling. This makes it ideal for creating prototypes and small batches of parts for testing and validation. It is also a cost-effective option for producing small to medium batches of custom parts.

- Short Lead Time: Because sheet metal fabrication does not require as many processing steps, its lead time is generally shorter than other manufacturing techniques.

Industries We Serve

Whatever industry you’re in, we have the experience and equipment to provide custom metalwork solutions that are both functional and beautiful. Whether you’re looking for industrial metalwork for heavy-duty applications, architectural metalwork to enhance your building design, or residential metalwork for a custom home project, we have what you need.

Aerospace

Automotive

Electronics

Industrial Equipment

Medical and Dental

Optics

Talk to us about your project

For a free quote, contact Xnparts and let us share our capabilities, commitment, and competitive pricing. Our engineers will be happy to answer your questions or prepare a free quote for your project. Contact Xnparts today and let us get started on your sheet metal project!