Metal 3D Printing

Industrial metal 3D printing processes can build fully functional metal prototypes and production parts in seven days or less using a wide range of metal materials.

Metal 3D Printing Service Provider

Xnparts has extensive experience in metal 3D printing, with a team of skilled operators and dedicated staff to ensure your project is a success from start to finish. With our experience in 3D metal printing, Xnparts has honed expertise in a variety of applications ranging from demanding, complex industrial parts.

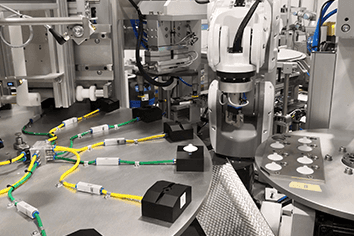

We offer both additive manufacturing and traditional manufacturing services on demand. From rapid prototyping to appearance models and mass production, Xnparts has state-of-the-art technology and the expertise to handle any metal additive manufacturing project. With our factory staffed by a team of experienced engineers focused on meeting your specific requirements as efficiently and quickly as possible, you can count on Xnparts for all your manufacturing needs. Whether you need a complex design or simplified manufacturing, our on-demand manufacturing services offer parts in a variety of metals and alloys.

The ideal solution for high-quality, complex metal parts

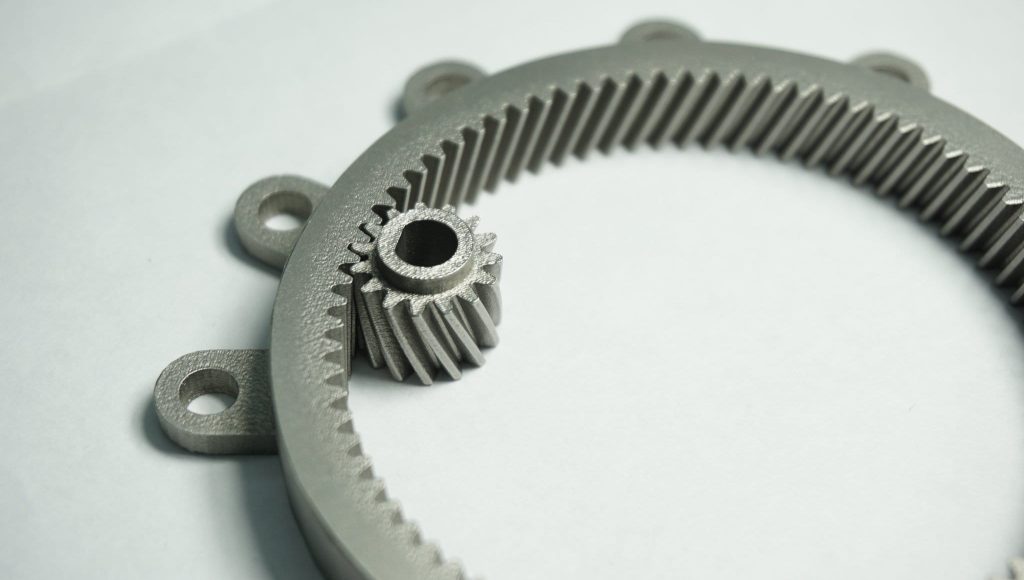

Using metal 3D printing to produce parts can make complex things simple. Metal 3D printing combines the design flexibility of 3D printing with the mechanical properties of high-performance metal alloys to create unique, strong and lightweight parts that can handle even the most complex applications. Metal 3D printing is ideal for manufacturing fully functional prototypes and end-use parts that may not be produced using traditional manufacturing methods. It can also produce high-mix, low-volume metal parts in an economical way. It also allows you to create complex part designs that are impossible to achieve using traditional methods. Xnparts’ team of engineers and production teams can help you make the most of metal 3D printing to quickly and flexibly manufacture metal parts. Whether you need a prototype or full series production, you can rely on us from start to finish.

Rapid Prototyping of Metal Parts

Metal 3D printing produces strong and durable parts. They can produce high tensile strength, hardness, and wear resistance in high-strength, lightweight materials for demanding applications. Such parts would be very expensive to produce using traditional manufacturing processes and could take months to produce. However, using metal 3D printing services can eliminate these upfront costs and enable metal parts to be printed on demand and produced quickly. This makes it ideal for rapid prototyping and can also help iterate on part designs and test part fit and performance. It enables designers to simplify assembly and create part designs that cannot be machined or cast. It can even be used for transitional production until production tooling is complete.

Ready to start your metal 3d printing project?

Get quality metal 3D printed prototypes and production parts. Request an online quote now.

Our Service Capabilities

Innovative Processes

Our metal additive manufacturing solutions support the production of lattice structures, part consolidation for lightweighting, complex internal channels for optimized fluid flow, and AM design (including topology optimization).

Services & Support

Our global team of application engineers provides engineering support, including design for metal additive manufacturing, process optimization, prototype development, and more. We also provide a range of services such as traditional machining and post-processing to meet your exact needs.

Rapid Prototyping

Provide rapid prototyping services to help you analyze the manufacturing feasibility of new product designs and prototypes of precision finished parts made from a variety of materials. Xnparts’ end-to-end solutions enhance the capabilities of any manufacturer and subcontractor.

One-Stop Service

Metal 3D printing can manufacture any type of metal part without the need for traditional tooling and with virtually no restrictions on geometry. Likewise, it complements traditional subtractive manufacturing methods and can be easily integrated into existing production operations.

Capability to 3D Printing Large Metal Parts

Xnpars’ large-format metal 3D printing is used for large, complex geometries and to simplify multi-part assemblies into a single design. The maximum size of a 3D printed metal part is 31.5” x 15.7” x 19.7”. For large geometries, we require a minimum 0.1” (2.54 mm) or 0.12” (3 mm) thick wall to achieve good performance and appearance results. We are uniquely positioned in this space to provide the right experience and technology for your project based on your material and application requirements. Leverage extensive equipment and metal 3D printing knowledge to meet your needs. Every step is customized to provide the best material, design, and end product for your specific application. Every conversation is a collaboration between our team and yours. Every result is designed to meet the needs of your operation.

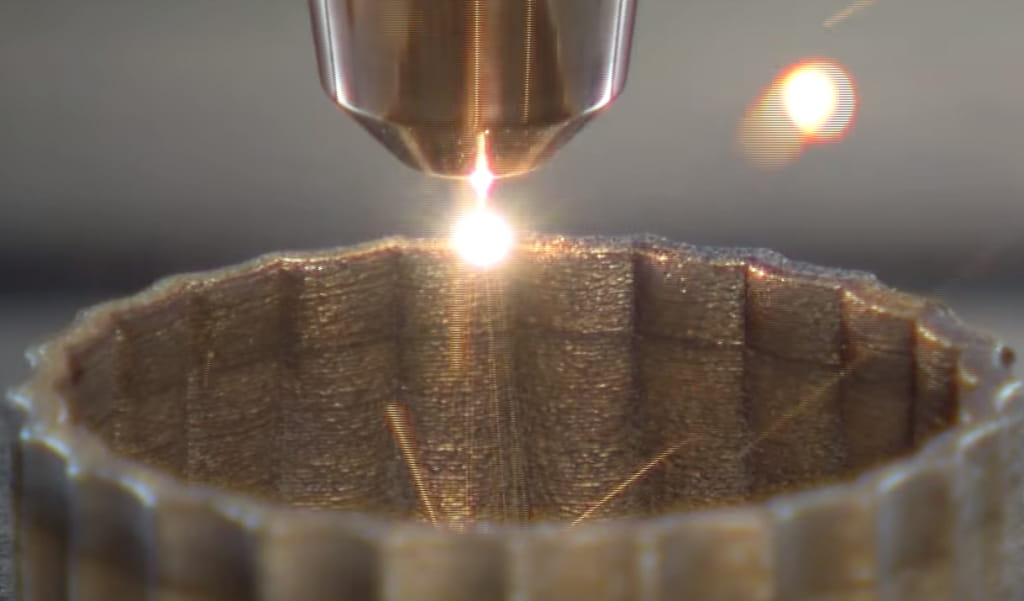

Types of Metal 3D Printing

Currently, Xnparts mainly provides 4 types of metal 3D printing technologies, including powder bed fusion, material jetting, binder jetting, and direct energy deposition. The widely used metal 3D printing technology is powder bed fusion, of which direct metal laser sintering (DMLS) and selective laser melting (SLM) are the most common technologies. And metal parts with complex geometries can be manufactured through DMLS/SLM.

Metal 3D Printing Material Options

The following are the metal alloys we have available for metal 3D printing. Xnparts’ material experts are standing by to help you select the best material for each product.

- Aluminum

- Titanium

- Steel

- Copper

- Stainless steel

- Cobalt-chromium

- Mold steel

- Tungsten alloy

- Magnesium alloy

- High temperature alloy

- Inconel

A variety of surface treatments and finishing processes

Surface treatments and finishing processes can be used to improve the strength, dimensional accuracy and appearance of the final metal part.

- Sandblasting (grit and ceramic)

- Shot peen

- Optical polishing

- Electrochemical polishing

- Abrasive flow machining

- Electroplating

- Micromachining processes (MMP)

- NADCAP heat treatment

- Hot isostatic pressing (HIP)

- Solution annealing

- Aging

- Polishing (mirror or brushed)

- Passivation

- Tapping and reaming

What is Metal 3D Printing?

Metal 3D printing is an additive manufacturing process that produces parts by fusing metal particles or powders together layer by layer to form metal components. It is often an alternative to CNC machining or metal casting because it can also produce parts with the strength and durability of metal while also taking advantage of the design freedom provided by 3D printing. It can produce complex designs, including lattices and topology-generated structures, both of which cannot be manufactured through traditional CNC machining. In addition, it helps to transform designs into scaled prototypes that are as close to the design model as possible. It is mainly used in the early stages of product development and can be used for concept models and functional prototypes.

Advantages of Metal 3D Printing

- Manufacture complex parts that are not possible with traditional manufacturing techniques

- Create conformal cooling channels and lattice structures

- Improvements in fluid dynamics

- Manufacture injection molded parts such as inserts and cores without tools

- Production of items such as orthopedic and dental components custom-made to individual specifications

- Manufacture parts with cavities, undercuts and draft angles

- Design lighter components to reduce overall weight.

- Applications in R&D projects

- Simplify assembly by combining multiple parts into fewer components

- Production of small, high-precision parts

- Topology optimization to ensure structural integrity while optimizing material distribution

Application of Metal 3D Printing in Various Industries

Xnparts provides advanced rapid prototyping and on-demand low-volume metal 3D printing production services. We provide you with complete design freedom to manufacture stronger parts that are lighter, more durable, and perform better than other methods. As a result, we can serve fully functional late-stage prototypes or end-use parts for any industry application.

Aerospace

Automotive

Electronics

Industrial Equipment

Medical and Dental

Optics

Request a Quote for Your Parts Now

Talk to a large-scale 3D metal printing expert today! Our team is standing by and ready to answer questions or provide a quote for your project.