Die Casting

Xnparts’ die casting services offer high-throughput production capabilities, low costs, and flexible part design options, making them an ideal casting choice for nonferrous metal products. Our die casting facilities are fully equipped to meet a wide range of design, material, and manufacturing needs across multiple industries.

Custom Die Casting Manufacturing Company

Xnparts offers a full range of advanced die casting services for both low and high volume production of metal parts. Our services are available for a variety of applications and include part casting, mold making, post machining and finishing services for completed parts.

Our die casting solutions work with a wide range of metal alloys, ensuring your project will be perfect for your end use. We manufacture parts with extreme dimensional accuracy, tight tolerances, and thin wall thicknesses where specified. From aluminum to magnesium and zinc, our casting machines and durable, finely detailed molds are our unique value proposition, ensuring we deliver parts of the highest standard and quality.

At Xnparts, we can use our die casting services to reduce your per-part cost. We can manufacture steel molds with rapid tooling to fit budget constraints when producing low volume production runs. From wet painting and powder coating to polishing and anodizing, our premium finishing solutions will enhance the overall appearance and beauty of your parts.

Metal Die Casting Service Capabilities

Whether it is a new design or an existing tool, we provide our customers with the highest quality aluminum and zinc die castings. Our capabilities include up to 350 metric tons of aluminum and zinc, and with 4-slide technology, we are able to produce complex castings to meet the specific needs and requirements of products across many industries. We also assist in the design of new, high-quality die castings, and can provide fast turnaround, custom finishes, and product assembly services.

When you submit your design to Xnparts, we use the die casting manufacturing process to create the perfect mold for you. We are precision casting experts located in Shenzhen, China, serving all regions around the world!

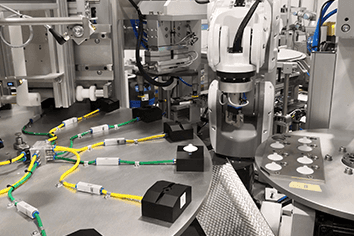

Our Service Process

The success of your die casting project depends on the quality of the mold, and our mold manufacturing capabilities are unmatched in Asia. After receiving your order, we will:

- Perform a complete manufacturing design review of your CAD files.

- Verify that the tooling and product raw materials are compliant.

- Use our multi-axis imported CNC machine tools to manufacture cores and cavities.

- Use careful heat treatment to temper the mold.

- Perform process control when casting parts.

- Provide any necessary post-processing or treatment.

- Expertly inspect and measure the finished parts to meet and exceed your specifications.

How to get started with us?

Our die casting services are unmatched, with the ability to create complex shapes, use a wide range of alloys, and achieve fast production. If you are ready to get started, choosing materials and an experienced injection molding partner is crucial. You can easily navigate with the help of our experienced professionals who will guide you to find the best solution for your specific project.

When you work with Xnparts, you can get die casting services for materials ranging from aluminum to magnesium and zinc alloys. You can get started by sending an inquiry and drawings to our company. After careful consideration, our managers will contact you and then begin the amazing realization process. Our state-of-the-art facilities and cutting-edge technology ensure that each casting is a masterpiece that meets the most stringent quality standards.

Ready to get started on your Die Casting quote?

Types of Die Casting We Offer

- Cold Chamber Die Casting: This method is ideal for high melting point metals such as aluminum, it reduces machine corrosion and offers a wide range of material options.

- Hot Chamber Die Casting: This is the most popular method, especially for low melting point metals such as zinc, it ensures efficiency without compromising precision.

- High Pressure Die Casting (HPDC): HPDC uses higher injection pressures, which increases part density, reduces porosity and enhances mechanical properties.

- Vacuum Die Casting: This method minimizes porosity in the final product by removing air from the mold cavity before metal injection, ensuring higher quality components.

- Multi-Slide Die Casting: Multi-Slide Die Casting allows complex and multi-cavity parts to be produced in a single operation, increasing efficiency and reducing production time.

Advantages of Xnparts die casting service

- Generally speaking, cold chamber die casting machines can die cast 50~90 times per hour.

- Hot chamber die casting machines can die cast 400 to 900 times per hour.

- The general tolerance grade of die castings is IT13~IT15 in GB/T 1800-2009, and the higher precision can reach IT10~W 1 1. The surface finish (Ra) is 3.2~1.6μm, and can reach 0.8μ locally.

- High mechanical properties of die castings

- The minimum wall thickness of aluminum alloy die castings is 0.5mm.

- The minimum wall thickness of zinc alloy die castings can be 0.3mm.

- Parts of other materials can be embedded in die castings – complex fasteners or inserts can be included in the final assembly. Therefore, it saves valuable material costs and processing costs.

- Parts with complex shapes can be obtained, improving the performance of parts and reducing assembly workload.

- Die castings with durable and dimensionally stable shapes can be obtained, so no processing or less processing is required.

- A wide variety of finishing techniques and surfaces can be applied to die castings. The process is capable of achieving either a smooth or textured part surface.

Material Options

Nonferrous alloy materials are often used for die casting because of their high dimensional stability. The most common alloys used for die casting are:

- Aluminum

- Zinc

- Copper

- Magnesium

- Tin

- Lead

Surface Finishing Services

Our metal castings can be finished using a variety of finishing solutions to give your parts the best possible look and performance.

- Standard

- Sandblasting

- Grinding

- Painting

- Powder Coating

- Electroplating

- Polishing

- Anodizing

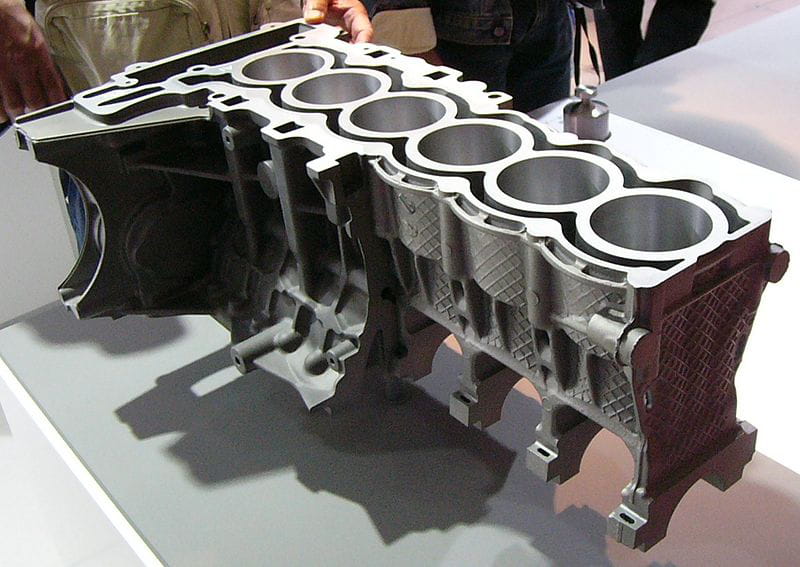

What is Die Casting?

Die casting, similar to injection molding, is a metal casting process in which molten metal is forced into a mold cavity to create a metal part. At Xnparts, we use certified machines and die casting molds to mold your design from molten metal (usually zinc, copper, aluminum, magnesium, lead, tin or other tin-based alloys). Our die casting process is effective and very reliable, and can save you a lot of money. Because of our flexibility, we can meet any of your project needs – from small batches of 50 pieces to as many as 1,000 pieces.

Characteristics of die casting

Die casting is a casting method in which molten alloy liquid is poured into a pressure chamber to fill the steel model cavity at high speed, and the alloy liquid solidifies under pressure to form a casting. The main characteristics of die casting that distinguish it from other casting methods are high pressure and high speed. Die casting is a precision casting method. The dimensional tolerance of die castings made by die casting is very small and the surface accuracy is high. In most cases, die castings can be assembled and used without turning, and threaded parts can also be directly cast.

- During the die casting process, the molten metal fills the cavity under pressure and crystallizes and solidifies under higher pressure. The commonly used pressure is 15-100MPa.

- The speed of the molten metal filling the cavity is very high, generally 10-50 m/s, and some can exceed 80 m/s (the linear speed of the cavity through the ingate – the ingate speed). Therefore, the filling and molding time of the molten metal is extremely short, about 0.01-0.2 seconds (depending on the size of the casting) to fill the cavity.

Top Die Casting Supplier in China

Are you looking for a reliable and fast die casting service provider? You have come to the right place! Xnparts is a leading die casting service provider in Asia. Our team of engineers, technicians and quality control experts work together to ensure your products are completed on time. As a top die casting supplier in China, we focus on new die casting technologies to produce complex parts with excellent dimensional accuracy and smooth casting surface. Our partners as well as our own factories produce high-precision die casting parts for customers from various industries.

Industries We Serve

Aerospace

Automotive

Electronics

Industrial Equipment

Medical and Dental

Optics

Start your die casting project today

Our die casting engineers are ready to work with you to ensure you get quality parts quickly. When you submit your 3D design files, we will consult with you to ensure design manufacturability so you get a part that meets or exceeds your expectations.