Injection Molding

Xnparts provides more than just injection molding services; we also provide comprehensive solutions for product design, mold design, prototyping, problem analysis and solving, and subsequent product improvements.

Custom Plastic Part Solutions

At Xnparts, we pride ourselves on being a leading provider of plastic injection molding services. With years of industry experience and expertise, we offer comprehensive solutions to meet your plastic injection molding needs. From concept to production, we are committed to providing high-quality, precision-engineered parts to your exact specifications. Our plastic injection molding services are fully customizable to meet your unique requirements. Whether you require a prototype, low-volume production run, or large-scale manufacturing, our team of skilled engineers and technicians is committed to delivering exceptional results. We work closely with you throughout the entire process to ensure that every detail is meticulously addressed, resulting in the high-quality parts that meet your expectations.

Custom Design Plastic Injection Molding to Your Needs

Xnparts provides high-quality plastic injection molding services to meet the diverse needs of customers from a wide range of industries. With our in-house capacity, engineering experience and state-of-the-art machine capabilities, we are able to provide rapid injection molding and on-demand production based on the specific needs of our customers. Our plastic injection molding solutions include overmolding, mold making, insert molding and multi-cavity molding. All of our processes are optimized to produce high-quality plastic parts and prototypes with outstanding appearance and excellent functionality. Our plastic injection molding technology is an efficient and scalable process that produces high-quality custom prototypes and production-level parts. We stock a variety of engineering-grade thermoplastic and elastomeric materials, allowing you to choose the best material to enhance the function and performance of your parts in your application. We also provide a range of finishing services to help enhance the aesthetics and protection of your parts.

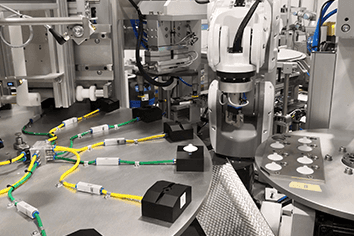

Cleanroom Injection Molding

Xnparts has begun expansion of our ISO 7 cleanroom primarily to accelerate urgent capacity needs of our customers and meet current cleanroom molding needs while accommodating long-term growth.

Through the use of cavity pressure sensors, scientific molding methods and state-of-the-art equipment, we are able to produce lower cost medical, biotech products in ISO Class 8 and Class 7 cleanrooms. We have molding machines ranging from 17 tons to 440 tons, each of our presses features self-diagnostics and microprocessor control, with a variety of shot sizes to meet the needs of any project.

Our Services

Custom Molding

Prototype Manufacturing

Rapid Prototyping

Product Design Services

Mold Design Services

Material Consulting Services

Production Services

Assembly Services

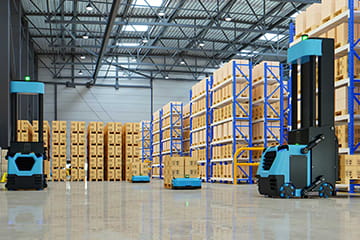

Warehousing Services

Our Process

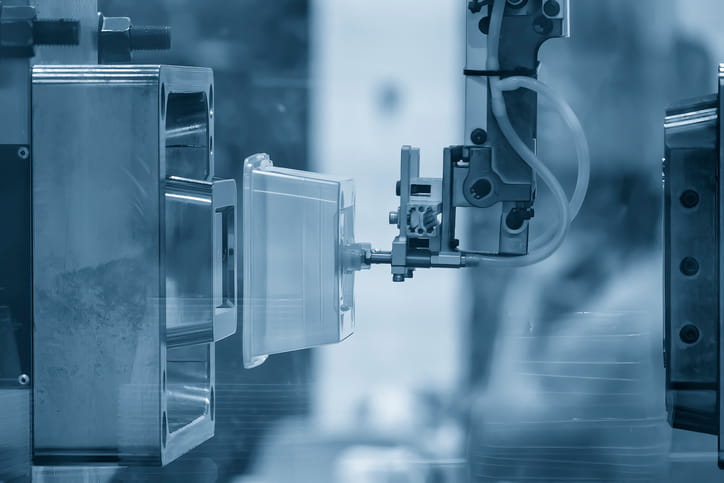

The first step is to verify that the injection mold design is suitable for manufacturing. Once verified, we can begin the injection mold manufacturing process. Once the mold is finalized, we begin preparations to begin plastic part manufacturing. Before full production begins, we will complete a trial run (T1) and inspect the parts for defects. We will share our observations with you and send sample parts for first article inspection (FAI). Based on the part requirements, we will establish quality standards and conduct process inspections throughout the production cycle. We use state-of-the-art equipment to check the parts for integrity, color correctness, and other common defects that may occur, such as flash, blushing, sink marks, and warping.

Once the sample is approved, we can begin production. Because Xnparts works closely with you to understand your ordering trends, we schedule accordingly to meet your immediate needs. Our goal is to have parts ready to ship from our plastic injection molding facility in Shenzhen, China, when you need them most. We also monitor the quantities on our shelves so that we can help you estimate future needs.

Ready to get a custom injection molding quote?

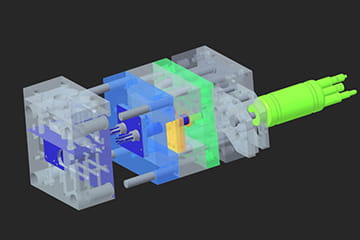

In-House Mold Manufacturing

All Xnparts customer molds are manufactured in-house at our manufacturing facility in Shenzhen, China. Our mold manufacturing area is staffed by experienced designers and machinists using state-of-the-art software and CNC machinery. Once the customer part design is finalized and approved for manufacturing, our team will design and build a solid, trouble-free plastic injection mold to your production requirements.

If your company needs to purchase new tooling for an injection molding project, you should want a single supplier that is responsible for the quality of both the injection mold and the production part. Xnparts’ ability to manufacture your own tooling can help you avoid facing serious quality issues, delivery time delays, and unforeseen costs in your budget.

Types of Injection Molding Processes

Thermoset (Reactive) Injection Molding

Molding with thermoset materials requires heat or chemical methods to cure the material. It uses a similar process to thermoplastic injection molding, but may use a hot mold instead of a cold one. It may also require a cure time instead of a cool time with the mold closed.

Overmolding And Insert Molding

Overmolding is a plastic injection molding process where one material is molded over another. This includes molding over part inserts, such as metal threads.

Gas-Assisted Injection Molding

After the plastic is injected into the mold cavity so that it only fills a portion of the cavity, an inert gas is introduced at high pressure to create an air pocket in the center of the part. This can reduce part weight while achieving a high-quality surface finish.

Co-injection and Bi-injection Molding

This process involves injecting two different materials using the same or different injection locations. One use case for this process is a product with a harder material as the base and a softer, more flexible material as the exterior to withstand a wider range of performance applications.

Microcellular Injection Molding

Uses physical blowing agents, chemical blowing agents (CBA), or a mold core retraction process to trigger the foaming of the polymer inside the mold. This is a way to reduce the weight of a part while maintaining its structural integrity.

Powder Injection Molding (PIM)

This molding technique uses a powder (usually ceramic (CIM) or metal (MIM)) and a binder (usually a polymer) to produce small parts. The processing of this material is similar to traditional injection molding.

Prototyping and Full In-House Services

Your product journey begins with Xnparts’ prototyping team. Our team of technical designers and engineers based in China can transform your company’s existing concepts into finished products. Our injection molding design team will transform simple sketches into fully realized CADCAM designs. Once approved, the final design is ready for the plastic injection molding process. Because we have the ability to design, provide prototype parts, build injection molds, and produce them ourselves, we are able to handle your parts and control the entire process from start to finish. As a result, you can enjoy the industry’s lowest costs and fastest lead times for the delivery of your plastic injection molding products. Our design team will meet with you to discuss your products and goals, as well as our processes and logistics.

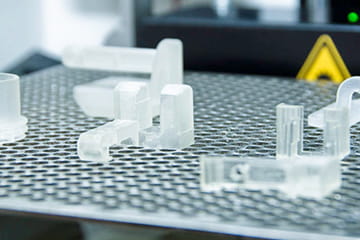

Plastic Prototyping Alternatives

3D printing manufacturing methods can produce prototype products faster than plastic injection molding. High precision and automated processes can produce parts and molds for prototype testing, thereby reducing costs. Customization options allow flexibility in part design and material properties such as color, transparency, strength and flexibility. If you are not sure whether the part or mold design is suitable for large-scale production, you can choose 3D printing for verification.

Plastic Materials

Our team of experienced staff is skilled in handling a wide range of injection molding materials. You are welcome to select any polymer from our list of options, which include:

- ABS

- ASA

- PS

- HDPE

- PEEK

- Polypropylene (PP)

- Polycarbonate (PC)

- PMMA

- Nylon 6/66(PA6/66)

- POM

- PLA

- PET

- PPS

- PCTG

- PC/ABS

Finishing Options

We offer different premium finishes to suit the various designs our customers may ask us. They include:

- Mold Textures

- Custom Color Matches

- Threaded Inserts

- Pad Printing

- Laser Engraving

- Basic Assembly

- Standard Finish

- SPI Finish

What is Injection Molding?

Injection molding is a manufacturing process used to produce precision, cost-effective plastic parts in large quantities. The process involves injecting molten material into a custom-designed mold, which primarily determines the shape of the part. After the material cools and solidifies, the mold opens and the part pops out. This process is ideal for making complex parts with tight tolerances and is popular because it can be produced economically in large quantities.

Advantages of Injection Molding

- The precision of injection molded parts is very high. Especially in the field of engineering, having precision-made parts can reduce wear and tear on moving parts. With precision down to 0.005 inches, you can expect everything to screw tight, fit snugly, and require less maintenance over time.

- A single, solid part is always better than having additional connection points. Injection molding is very versatile, and many times, parts can be molded as a single piece without any screws or potential weak links.

- The flexibility of plastic selection makes injection molding a good choice for almost any plastic. Plastics vary greatly in tensile strength, durability, and flexibility.

- Specialized high-strength fillers can be added during the injection molding process to enhance the strength of the finished product.

- With injection molding, a smooth surface on a part can be easily achieved. Without the need for additional surface treatment, this efficiency saves time and money.

We Are Your Injection Molding Partner

At Xnparts, we know that our customers are our reason for existence. We are nothing without you, and your business is our business. Building true partnerships with our customers allows us to gain a deep understanding of your business and its unique challenges. This understanding allows us to propose tailored solutions to meet your needs. We work closely with you to identify opportunities to reduce costs and improve quality. When we design your part or mold, we do so based on a thorough understanding of the manufacturing process: from the injection molding cycle to cost and cycle time targets. Although every project is different, our proven processes and standards help us consistently achieve the best results for our customers across all industries.

Industries We Serve

We combine our extensive experience with the latest technology in the industry to provide you with dynamic and cost-effective injection molding solutions. In addition, we have a diverse team of designers and engineers who are professionals in different fields. This enables us to meet the needs of many industries with rich expertise.

Aerospace

Automotive

Electronics

Industrial Equipment

Medical and Dental

Optics

Ready to start your next project?

Gain precision and speed with our injection molding services. Get custom prototypes and production molded parts efficiently. Submit your design today for a free quote!