CNC Machining

We provide one-stop custom CNC machining solutions, providing comprehensive support and services for your project needs. From design to production to delivery, we have a professional team and advanced equipment to ensure that we can provide you with high-quality, high-precision custom parts.

One-stop CNC Parts Manufacturer

Are you looking for a reliable and fast CNC machining service provider? We excel in developing and applying advanced manufacturing solutions to meet our customers’ complex needs and the precise tolerances they demand. We plan and schedule jobs to meet tight deadlines and tackle some of the industry’s largest and most challenging projects. Our capabilities include 3, 4 and 5-axis CNC milling and turning, grinding, EDM, laser cutting and more. From design and rapid prototyping to handling complex part geometries and low-volume and high-volume production, we are your one-stop shop for your CNC machining needs. Each CNC or manufacturing service is tailored to meet specific business needs. Our engineering and design teams work closely with our customers to bring concepts to reality using their technical expertise and innovative thinking. Our goal is to provide high-quality machined parts that meet your budget and delivery time requirements.

Our CNC Machining Capabilities

Xnparts has everything you need to produce the best custom CNC parts to satisfy our diverse customer base. With a wide range of CNC machining capabilities, we have the expertise to handle any project and meet exact specifications.

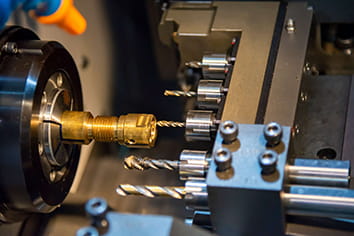

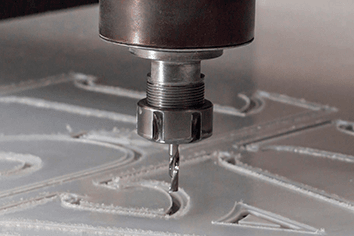

CNC Milling Services

CNC Turning Services

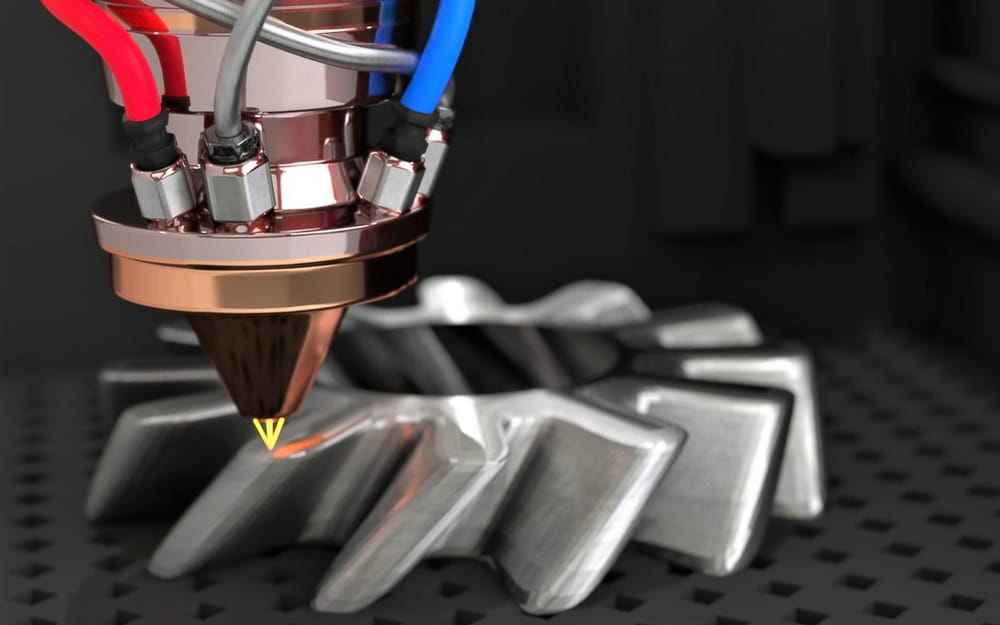

EDM and Wire Cutting Services

CNC Grinding Services

Swiss Machining Services

CNC Routing Services

CNC Machined Parts Tolerances

A reliable CNC machining company always dares to promise, promises that all CNC machining parts will be manufactured in strict accordance with your requirements and design specifications, and implemented in accordance with the ISO 2678 tolerance standard.

- Resistance Range: ±0.008mm~0.010mm

- Tube shaped Circumference 0.01mm/100mm

- End Face Flatness 0.02mm/200mm

- String Pitch Accuracy 0.06mm/300mm

- Harshness: Ra0.8

- Worldwide Tolerance Level: IT6-IT8

- External Circle Accuracy 0.005mm-0.01mm

- Surface Finish After Grinding Machine Can Reach Ra0.4

Ready to get a CNC machining quote?

Once you send us your 3D CAD file for a free quote, one of our customer service engineers will check the manufacturability of your design to ensure the part can be manufactured to your expectations and budget requirements.

One-stop manufacturing solution

At Xnparts, whether you need a prototype to verify your design or mass produce the final product, we can provide you with the best on-demand production solution.

Rapid Prototyping

Low-volume and high-volume production

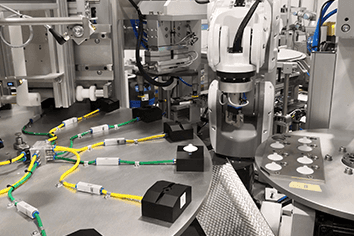

Quality Control

Sampling inspection based on AQL or 100% inspection using automated testing equipment is performed as needed. Assembly inspection can also be performed if necessary.

IQC

- Material certifications and certificates of conformity

- In-coming inspection reports

PQC & IPQC

- Every 5-10 pieces will be inspected, during machining

- Timely detection of defects in each production batch

- Setups will be adjusted promptly when defects are found

FQC

- Take comprehensive and final inspection and testing

- Sampling plan complies with AQL standards (ISO 2859-1)

- Including appearance inspection, dimension/hole diameter measurement, and performance testing

QQC

- Check packaging status, shipping marks and related docs or reports

- Quality inspection/quality audit before shipment

Material Options for CNC Machining

At Xnparts, we offer a wide range of materials to meet the various needs of our customers. Our commitment to excellence ensures that every custom CNC machined part we produce is of unparalleled quality and precision. Whether you need a metal component with exceptional strength or a plastic component with excellent mechanical properties, our material selection meets the needs of a wide range of industries and applications.

Metal materials

- Stainless steel

- Aluminum alloy

- Brass

- Titanium alloy

- Tool steel

- Copper alloy

- Nickel alloy

- Cast iron

Plastic Materials

- ABS (Acrylonitrile Butadiene Styrene)

- PEEK (Polyether Ether Ketone)

- Nylon

- Polycarbonate

- PVC (Polyvinyl Chloride)

- Acetal

- HDPE (High-Density Polyethylene)

- PTFE (Polytetrafluoroethylene)

Surface treatment options

- spray painting

- powder coating

- anodising

- hard anodising

- thick film oxidising

- conductive oxidising

- micro-arc oxidising

- passivation, phosphating

- sandblasting

- Teflon spraying

- shot blasting

- electroplating

- radium engraving

- silk-screening

- brushing

- mirror polishing

- dyeing

- blackening

- CD texture

- etching

- high-gloss

- etched

- dripping

- electrophoresis

What is CNC machining?

Computer numerical control (CNC) machining is a subtractive manufacturing process that uses a machine tool to remove portions of material from a workpiece until the desired shape is achieved. CNC equipment utilizes a computer program (also known as G-code) to control the sequence in which the CNC machine tool or workpieces move relative to each other to create the desired part. Standard CNC machines include multi-axis CNC mills, lathes (or turning machines), and routers. While all CNC machine types rely on computer instructions to perform subtractive manufacturing, their modes of operation differ slightly.

Benefits of CNC Machining

- Improved accuracy and repeatability

- Increased efficiency and productivity

- Reduce waste and material usage

- Consistency in quality and dimensions

- Improved safety and reduced manual labor

- Increased versatility and ability to produce complex shapes

- Flexibility to produce small or large batches

- Improved precision and surface finish

- Minimized downtime for setup and tool changes

- Increased cost effectiveness over time.

Tips for Precision Machining

Avoid holes that are too deep

The effective cutting edge length of the milling cutter is limited, and the correct hole depth design can help reduce machining time and machining costs.

Limit thread depth

Sometimes deep threads are not needed at all. It is usually best to design the thread depth to be 1.5 to 3 times the diameter of the threaded hole.

Avoid excessive tolerances

Note that overly tight tolerances will increase machining difficulty and cost. Therefore, narrow tolerance requirements should only be specified when necessary.

Standard size holes

Standard size holes can be CNC machined with standard drills with high accuracy and speed. This can save machining costs compared to non-standard size holes.

Avoid excessive aesthetics

Putting the accuracy of necessary features above aesthetics will help improve your design because aesthetic requirements can be achieved through fine machining.

Avoid thin walls

Thin-walled parts are more difficult to precisely machine, and to reduce machining costs, the minimum thin wall thickness for metal parts should be 0.8mm, and the minimum thin wall thickness for plastic parts should be 1.5mm.

Avoid features that are too small

Features that are too small, such as those with a diameter less than 2.5mm, will increase the difficulty and cost of machining, so they should be avoided unless necessary.

Correct thread size

It is recommended to use thread sizes of M6 or above, and it is also important to avoid using thread sizes less than M2, and it is also important to avoid designing holes that cannot be tapped.

Alternatives to CNC Machining Services

While CNC machining services are suitable for manufacturing many types of parts, they also have limitations. For example, it cannot be used to manufacture complex internal features, such as internal cavities or arched cooling channels. If your design has these features, you may choose to manufacture them through additive manufacturing methods such as metal or plastic 3D printing. In addition, for certain types of flat workpieces, laser cutting, water jet cutting, wire cutting, and photochemical etching may be more effective.

Industries We Serve

Xnparts provides excellent global service with a large and rapidly growing customer base. Our customers are located all over the world and come from all walks of life. We will always do our best to meet your design and manufacturing needs and help you turn your ideas into reality.

Aerospace

Automotive

Electronics

Industrial Equipment

Medical and Dental

Optics

Start your project now!

Our team of engineers will contact you within 1 hour. We will be happy to answer your questions.