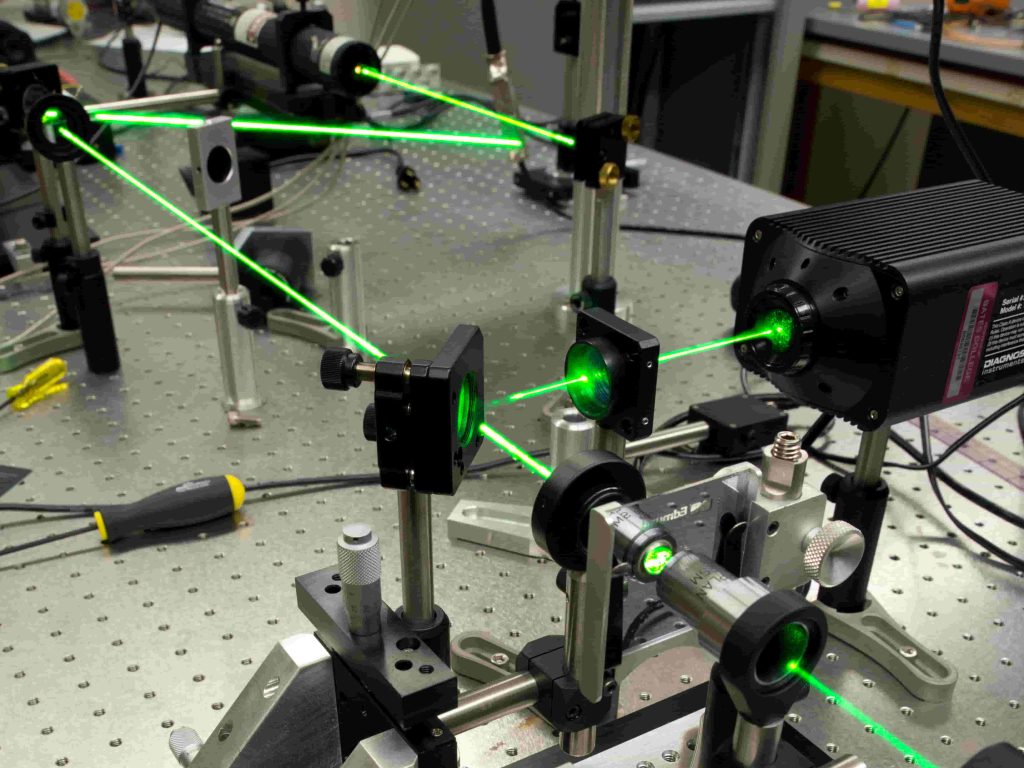

Optics

Xnparts has a deep understanding of optoelectronic devices, world-class optical component design, excellent mechanical engineers, and many years of experience in developing and producing custom parts for optical systems. It is committed to meeting the unique needs of each customer and providing optimized solutions.

Optical Components Manufacturer

Xnpart has deep expertise in custom parts for optical device systems. We have been manufacturing complex custom optical components, or combining them as needed to form complete optoelectronic solutions. And we perform all services in-house to obtain the highest precision results in the shortest time.

This seamless integration is our hallmark. If timing is critical to the success of your product development, we can provide optical components and precision optical custom parts in as little as three weeks. Our extensive knowledge and capabilities mean that we can shorten cycle times and provide custom solutions by recommending the right methods and at the right time. When you are ready to manufacture, we have identified and resolved potential production issues and installed custom metrology equipment to test quality to the level you need and the tightest tolerances in the industry.

Xnparts Solutions and Benefits

Xnparts solutions are able to provide optical manufacturers and design engineers with analysis results to verify the complex designs of optical system components. With Xnparts, optical designers and manufacturers can identify certain potential problems early on through the entire manufacturing process of rapid prototyping. Therefore, utilizing rapid prototyping services can be very powerful and effective in obtaining suitable solutions. In addition, it can help optimize part/mold design or process conditions to improve the quality of optical parts. In addition, Xnparts can test and export deformed shape and refractive index data for optical analysis in CodeV. This integration allows designers to confirm or modify their designs. On the other hand, Xnparts optical parts manufacturing services can be extended to a very large number of processes, including traditional manufacturing processes.

Contact us to start your project today!

Optical manufacturing capabilities

We strive to achieve the highest quality and precision benchmarks in the field of optical component manufacturing, ensuring that the products we provide have the highest efficacy and reliability. If you require unparalleled precision in your optical components, contact Xnparts to learn how we can meet your needs.

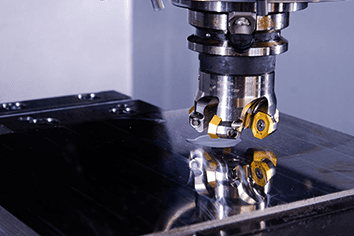

CNC Machining

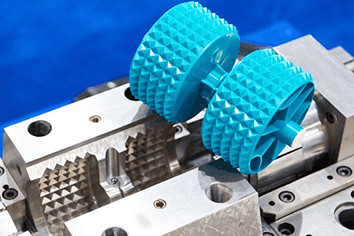

Plastic Injection Molding

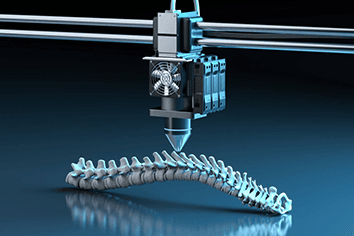

3D Printing

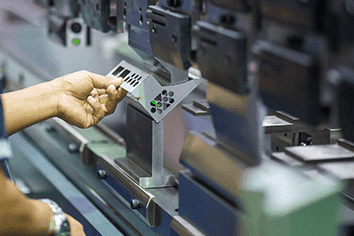

Sheet Metal Fabrication

Vacuum Casting

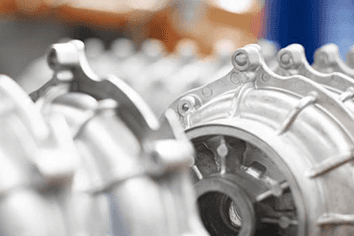

Die Casting

Optimized Optical Manufacturing

Our vertically integrated production facilities accelerate your time to market for new or existing products, with part design, DFM, mold design, in-house tool manufacturing, injection molding, CNC machining, 3D printing, and QA all under one roof. From rapid prototyping to mass production, Xnparts can streamline production lines through automation when necessary to achieve the optimization you need. Xnparts’ global supply chain allows us to meet your production needs directly at our manufacturing facilities. No matter where in the world your optical components need to be sent, our optical components can be shipped on time and provide the same performance.

Optical Component Material Options

We use high-quality materials to ensure that the components we manufacture are of the highest quality. We can design components made from a variety of materials, such as:

Metals

- Alloys

- Aluminum

- Brass

- Copper

- Stainless Steel

- Precision Steel

- Titanium

- Special Alloys

Plastics

- Alloys

- Aluminum

- Brass

- Copper

- Stainless Steel

- Precision Steel

- Titanium

- Special Alloys

Surface finishing

- Texturing

- Anodizing

- Polishing

- Blasting

- Painting

- Electroplating

- Passivation

- Heat treatment

- Powder coating

- Custom

Optical Parts Customization Service in Compliance with Global Quality Standards

Xnparts is a professional custom parts manufacturing service provider, producing in compliance with international quality standards. We specialize in TV LED beams, lens mounts, lens barrels, lens spacers, lens holders, lens hoods, optical mouse lenses and transparent parts, etc.

Our main advantage is our ability to produce spherical and aspherical optical lenses, mirrors, mold inserts, free-form optics and mechanical components with sub-nanometer surface finish and sub-micron precision. We use a wide range of materials to provide our customers with the best custom parts solutions for ultra-precision applications in the field of optics.

The combination of lens molding and optical molding shapes the future of optics

In the field of optics, the fusion of optical molding and lens molding is reshaping the industry. Optical molding facilitates the large-scale and cost-effective production of durable non-glass lenses, overcoming historical issues of fragility and cost. This collaboration enables the manufacture of high-quality lenses with perfect optical surfaces, positioning plastic optical lenses as a resilient alternative in a variety of applications.

The integration of optics and lens molding prioritizes efficiency and innovation in the field of optics. Plastic optical lenses made with precision molding processes become durable alternatives that meet the needs of modern applications. This collaborative approach not only ensures large-scale production, but also marks a strategic shift towards a future of advanced and accessible optical solutions. The journey of combining optical molding with lens molding heralds a transformative future where optics will seamlessly combine durability, precision and cost-effectiveness.

How we manage custom optical projects

The challenges of managing optical projects are considerable. Optics is a highly specialized discipline that requires detailed knowledge of optical design, mold making techniques, state-of-the-art machining capabilities, and optical metrology expertise.

As a result, we can perform the following key project management tasks:

- Determine realistic goals for product performance

- Develop a mechanical design optimized for injection molding

- Evaluate the pros and cons of different tooling approaches

- Develop a realistic program schedule and assign appropriate milestones

- Understand potential project risks and develop appropriate mitigation strategies

- Develop a quality assurance plan that is compatible with manufacturing processes and available metrology equipment

Let us know what custom optical parts you need today

Our experienced team of designers, technicians and engineers use their extensive knowledge to produce a range of optical components with varying application consistency. Get started on your next project now and contact us for a quote.