Industrial

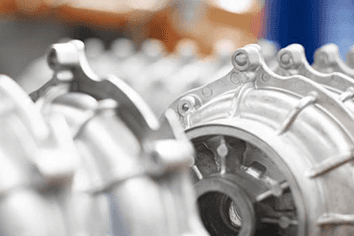

Xnparts can provide a wide range of components for industrial manufacturing. We have extensive experience in engineering, machining and molding hundreds of manufacturing components, providing a broad platform of experience for your project.

Industrial Equipment Parts Manufacturer

Xnparts can provide custom manufacturing solutions for precision parts for the industrial market. When designing industrial equipment parts, you are often faced with demanding requirements for product applications. Whether it is extreme operating temperatures, corrosive chemicals or high-impact applications, industrial customers need a manufacturer that excels in machining relevant custom parts. They also need a supplier who can provide product design assistance for these challenging parts. Xnparts provides a fast and reliable industrial on-demand option. Meeting the growing demand for industrial equipment parts while still supporting traditional equipment and machinery with custom parts. All prototypes we provide are manufactured to precise specifications and represent the true properties of the final product and accelerate the production of industrial equipment and parts.

Comprehensive Manufacturing Capabilities for the Industrial Equipment Industry

Do you need a large supplier to produce a large volume of parts? High-volume suppliers don’t typically get involved in short-term or new product innovation (NPI) work. Their infrastructure requires them to focus on long-term production for you and other manufacturers. But Xnparts can provide short-term and long-term on-demand manufacturing services. When you need help with:

- Improving the design of new parts and assemblies?

- Are your designs analyzed for manufacturability?

- Prototype parts to verify fit, finish, and functionality?

- Bridging and low-volume production until production tooling is ready?

- Reverse engineering and producing old service parts on demand?

- Looking for industrial 3D printing services that can meet these needs?

Industrial Equipment Solutions

Industrial equipment manufacturers face many common challenges that our experienced engineering and production teams can address:

- Design for Manufacturability (DFM)

- Optimize for advanced applications

- Part consolidation

- Lightweighting

- Eliminate or simplify tooling

- Reduce part lead times

- Lower costs

- On-demand production of service parts

Ready to start your project?

Speak with an automation industry expert today! Our team is standing by and ready to answer questions or provide a quote for your project.

A process to meet your industrial equipment manufacturing needs

From the moment you start talking to our engineers, they will work closely with you to understand your needs and perform a Design for Manufacturability (DFM) analysis. This helps ensure that all potential part design issues are discovered and resolved early in the product development process. Helping you optimize part design, production processes, and material selection to get the best results at the best price. Our experienced engineers can help you move your project from prototype to production with confidence.

Industrial Manufacturing Capabilities

Backed by years of experience, we have a deep understanding of the automation industry and the needs of its customers. Coupled with our robust equipment range and dedicated staff, this enables us to deliver precise, flexible and tailored manufacturing solutions that ensure reliability, efficiency and ongoing satisfaction.

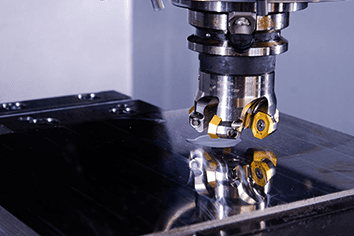

CNC Machining

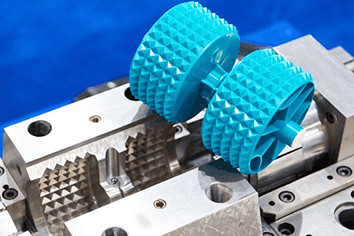

Plastic Injection Molding

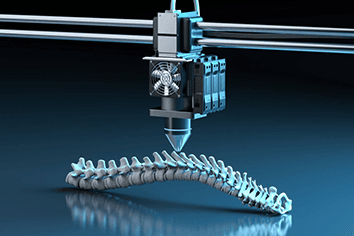

3D Printing

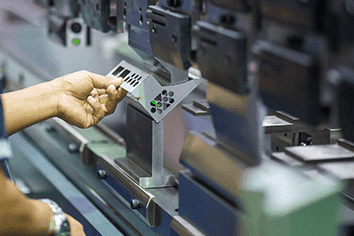

Sheet Metal Fabrication

Vacuum Casting

Die Casting

Industrial manufacturing materials

Our engineering team can help select the best material options. Our customers benefit from our extensive experience working with materials for demanding mechanical, chemical, harsh environment, and UV applications. Materials used by Xnparts include:

Metals

- Alloys

- Aluminum

- Brass

- Copper

- Stainless Steel

- Precision Steel

- Titanium

- Special Alloys

Plastics

- Alloys

- Aluminum

- Brass

- Copper

- Stainless Steel

- Precision Steel

- Titanium

- Special Alloys

Industrial post-processing capabilities

- Texturing

- Anodizing

- Polishing

- Blasting

- Painting

- Electroplating

- Passivation

- Heat treatment

- Powder coating

- Custom

OEM Contract Manufacturer for Industrial Sector

Xnparts can meet and exceed the most stringent requirements of any OEM partner. We guarantee that we will bring products to market faster and with fewer design iterations than any other manufacturer in the industry. We practice value-added thinking in our daily work and every project. Therefore, we have adopted many cost-effective production techniques to provide the best value to our trusted partners.

In addition, we provide strong Design for Manufacturer (DfM) guidance so that our partners can bring the quality products we manufacture to market at unparalleled speed.

We are the first choice of OEMs for our comprehensive manufacturing capabilities, agility, timeliness and commitment to quality. We serve a variety of OEMs in the industrial market and provide the best value for customer project requests.

Our After-Sales Service

At Xnparts, our responsibility for a project doesn’t end when it’s completed. We offer a comprehensive after-sales service to ensure that our customers get the support they need even after the product has been delivered.

Our experienced team of professionals is dedicated to providing timely assistance and resolving any issues that may arise. Whether it’s resolving technical issues, providing maintenance services, or replacing defective parts, we go to great lengths to ensure that our customers are completely satisfied with our work. We are committed to building long-term relationships with our customers, and our after-sales service is just one of the ways we demonstrate that commitment.

Ready to discuss your industrial equipment project?

Xnparts can help you through a range of transformative processes that bring much-needed speed, intuition, reliability and flexibility to your supply chain and internal processes. Upload your CAD design prototype and contact us now. Our engineers will provide you with a free quote and design for manufacturability analysis to start production discussions immediately.