Medical

Xnparts provides reliable medical device prototyping and production, from simple to complex medical parts. No matter the complexity of the part, we can help you achieve your goals through rapid prototyping, bridge tooling and low-volume production.

Custom Medical Parts Manufacturer

Do you need help turning your medical product concepts into viable prototypes and production parts? Are you a medical device manufacturer looking for a manufacturing partner with extensive expertise in a variety of technologies to help you get your medical products and ideas to market faster?

Xnparts has many years of experience specializing in medical device prototyping and medical parts processing, and has served many medical device manufacturers around the world. We will help you every step of the way, from the first prototype, to testing and iteration, to new product demonstrations, and even short or low-volume production. Providing a full range of rapid prototyping and manufacturing solutions for the medical industry through creative and agile manufacturing technologies such as 3D printing, injection molding, polyurethane casting, and precision CNC machining. From surgical tools to large-scale treatment units, our engineering approach will help you move from initial ideas to viable plans.

Turnkey Medical Device Solutions

Xnparts works with medical device OEMs to provide turnkey solutions for their long-term manufacturing programs. Our programmatic approach provides full control of prototype development, sourcing, product quality, kitting and assembly, inventory control, and on-time delivery of medical products from start to finish. We will work with you to ensure success throughout your project. Whether you need a prototype, custom device, or mass-produced assembly, we deliver reliable and consistent results on time.

Quality Management

Due to the importance of medical devices, the medical industry requires parts with extremely high precision and stable quality. Any deviation may cause product failure and endanger patient safety. Xnparts’ engineers and quality management team will carefully check the drawings and processing details at every step of each processing process, from prototype to small batch production to large-scale production. During the prototype stage, customers usually continue to optimize the drawings. In this process, it is very easy to ignore details and cause quality problems, which is unforgivable for our company. Because this is the premise to ensure that customers receive standardized parts that meet their needs every time.

Ready to build your custom medical prototypes and parts now?

If your medical project requires precision CNC machining services, contact our experts directly today or request an instant quote online today!

Medical Manufacturing Services

We have a deep understanding of the medical device and equipment industry and the needs of our customers. Coupled with our robust equipment line and dedicated staff, we are able to provide precise, flexible and tailored manufacturing solutions that ensure reliability, efficiency and ongoing satisfaction. Below are the various manufacturing capabilities we offer.

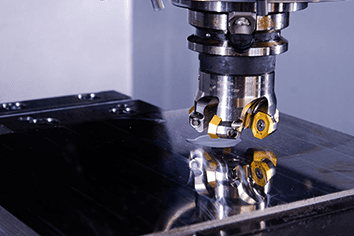

CNC Machining

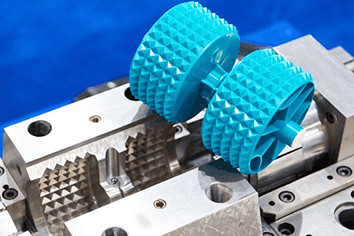

Plastic Injection Molding

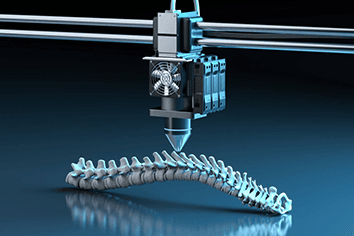

3D Printing

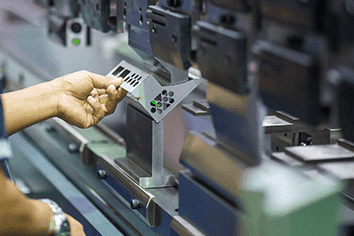

Sheet Metal Fabrication

Vacuum Casting

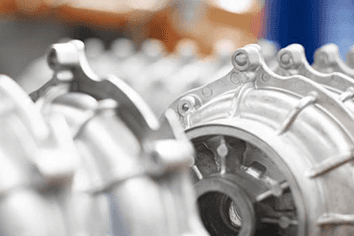

Die Casting

3D Printing Drives Innovation in the Medical Industry

3D printing, or additive manufacturing, is also an ideal way to manufacture medical products. 3D printing can quickly produce individual components, making it easy to create complex geometries for applications such as prosthetics or medical models. This rapid prototyping method allows for fast and inexpensive iteration of designs for efficient debugging, making it ideal for early evaluation of new medical parts. The biggest advantage of 3D printing is the ability to perform precise form and fit testing, while the disadvantages are limited materials, colors and textures, and a lack of surface finish.

Importance of Rapid Prototyping in Medical Device Development

Designing and developing new medical devices can be expensive and time-consuming. Rapid prototyping services can help you bring your new medical devices to market efficiently and cost-effectively.

Rapid prototype manufacturers can quickly, consistently and cost-effectively provide prototypes with basic functions and production parts in small batches for concept and market testing of medical devices and healthcare products. This can help device manufacturers analyze design flaws, collect early customer feedback and develop fit-for-purpose solutions to put them into the lab or clinical trials and ultimately bring them to market faster. And in the process, they can also gain insight into subsequent manufacturing processes, costs, timelines and quality control.

Material Options for Medical Components

Depending on the component type and required application, different metal or plastic materials can be selected to manufacture medical-related parts applications.

Metals

- Alloys

- Aluminum

- Brass

- Copper

- Stainless Steel

- Precision Steel

- Titanium

- Special Alloys

Plastics

- Acetal

- Delrin

- Nylon

- PEEK

- PTFE

- PVC

- Ultem

- UHMW

Material Compliance

It is critical to ensure that materials meet regulatory standards such as biocompatibility and sterilization compatibility. The materials of many medical device components must comply with FDA, ISO and other relevant medical standards. We have domestic material supplier channels that meet safety standards. For special materials, we also import raw materials from Europe and the United States to meet customer product requirements and provide material certification reports to ensure that there are no material problems with the parts produced. Our customers can put their medical products on the market with confidence.

Surface treatment

- Anodizing

- Passivization

- Electroplating

- Powder Coating

- Insert Installation

- Heat Treatment

Medical Parts Applications

We work with customers in the medical field to enhance medical device manufacturing for a variety of healthcare applications. Some typical components we produce for medical devices and applications include:

- Cartridges

- Ventilators

- X-Ray equipment

- Dental prosthetics

- Orthopedic implants

- Prosthetic components

- Implantable prototypes

- UV sanitation components

- MRI devices

- Medical carts

- Anatomical models

- Biomedical sensors

- Microfluidic devices

- Medical treatment devices

- Medical monitor instruments

- Medical diagnosis equipment

- Medical device motor housing

- Ultrasonic equipment

- Medical testing devices

- Physiotherapy apparatuses

- Medical imaging components

- Optics for medical instruments

- Drug delivery device components

- Medical device enclosures and housings

Why Choose Xnparts to Manufacture Your Medical or Dental Project?

Customers choose us to manufacture their medical and dental projects because of our expertise, quality, and reliability. We have a team of skilled professional engineers and machinists who specialize in medical and dental manufacturing, allowing us to provide our customers with customized solutions for their unique needs. Our commitment to quality is reflected in every step of the production process, from sourcing the best materials to employing a rigorous quality control system. This ensures that our products meet the highest standards of safety and effectiveness. In addition, our reliable production process means that our customers can rely on us to deliver their projects on time, every time. Finally, our excellent customer service means that we work closely with our customers to ensure that their requirements are met and that they are satisfied with the final product.

Ready to start your project?

Speak with a medical device and equipment industry expert today! Our team is standing by and ready to answer questions or get a quote for your project.