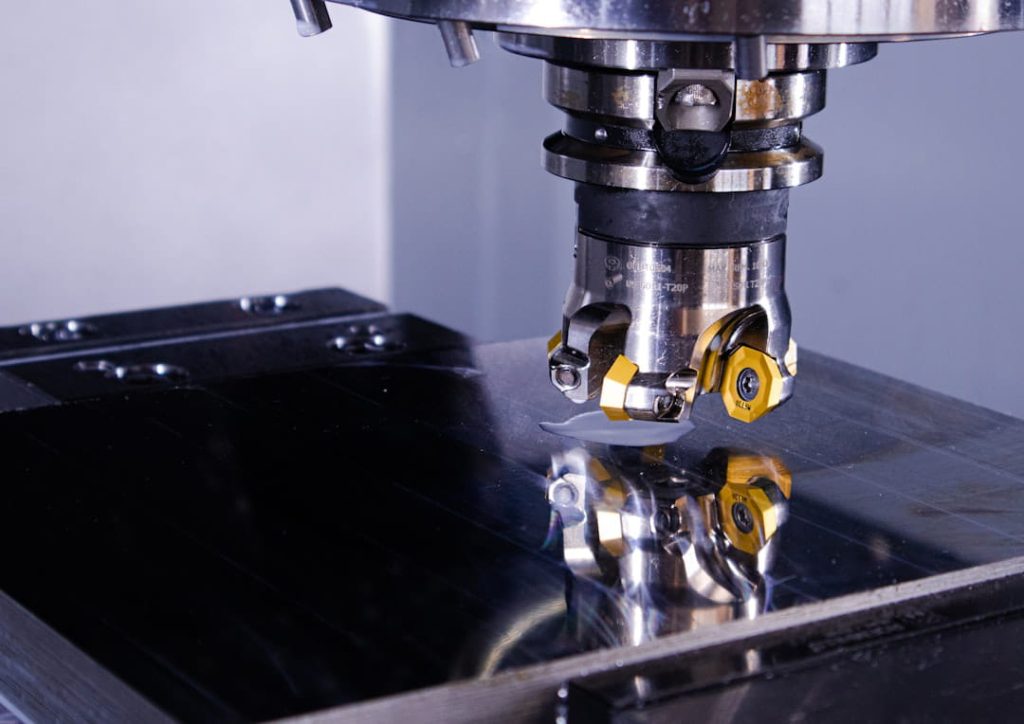

CNC Milling

Providing on-demand CNC milling services for rapid prototyping and production parts. Whether you need low-volume prototype parts or high-volume production, Xnparts can be your manufacturing partner.

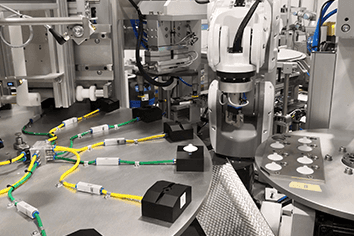

CNC Milling Service Provider

Xnparts is a professional CNC machining service provider with advanced 3, 4 to 5 axis milling centers. We provide custom CNC milling services to various industries around the world. We have a team of highly qualified engineers and machinists and a dedicated quality control team to test and ensure that all CNC machined parts meet customer requirements and required standards and regulations. We focus on providing tailor-made solutions for our customers. Our team works closely with each customer to ensure that we understand their specific needs and goals.

At Xnparts, we can provide comprehensive design and consulting services. Our team of experts can help you improve product design, optimize manufacturing processes and identify cost-saving opportunities. Whether it is a complex production run or a design consultation, we are committed to providing first-class service that exceeds expectations. Our experienced engineers, designers and procurement department ensure that we can efficiently and cost-effectively meet all project needs from prototype to mass production. By working closely with our customers, our goal is to provide tailor-made solutions that not only meet their current needs but also help achieve long-term success.

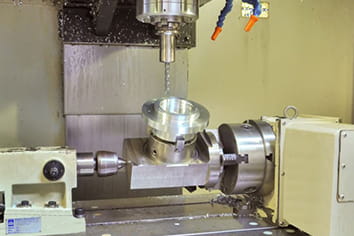

CNC Milling Capabilities and Specifications

Our vertical and horizontal CNC milling machines can hold tight tolerances including 0.0002″ diameter, profile accuracy down to 0.0015″, positional accuracy down to 0.0014″, and flatness down to 0.002″. We can hold these precise tolerances on different metals, exotic metals, plastics, and other materials to meet your specific design needs, including GD&T callouts. Depending on your part geometry and selected material, we offer standard and custom thread sizes with tolerances as close as ±0.001″. Our default CNC milling tolerances for metals follow ISO 2768-m, and for plastics we follow ISO 2768-c.

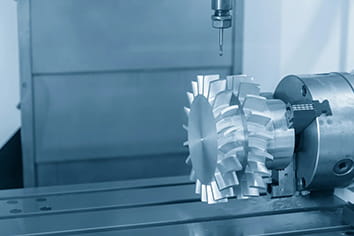

Types of CNC Milling Processes We Provide

We offer a variety of CNC milling services including 3-axis, 4-axis and 5-axis to create metal or plastic parts with complex geometries with high precision. This helps customers control and ensure that custom parts meet their exacting project requirements.

3-axis CNC milling

4-axis CNC milling

5-axis CNC milling

Ready to start your project?

Talk to a CNC milling expert today! Our team is standing by and ready to answer questions or provide a quote for your project.

Additional Processing

No matter how complex your part design is, we offer a variety of processing capabilities to achieve it. Including: Boring, Broaching, Counterboring, Countersinking, Drilling, Facing, Gear hobbing, Knurling, Parting/cutting, Pocketing, Profiling, Reaming, Splining, Tapping, Threading.

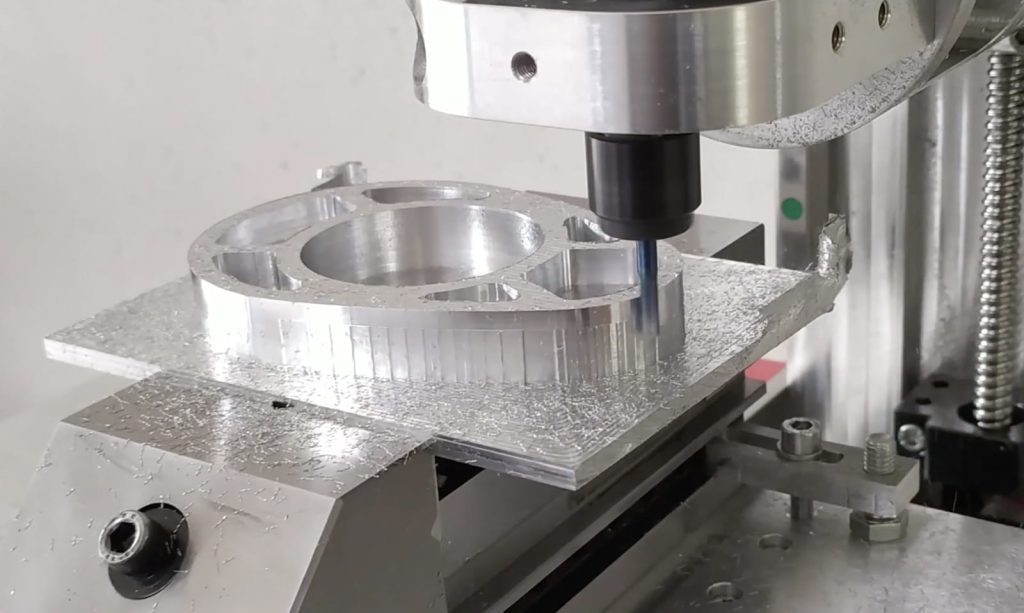

Material Options

We offer a wide variety of materials for custom CNC milling, plastics, and metals, if your project requires a material that is not listed, please let us know! We can accommodate other material requests, but it may take more time to quote while we source the material.

Metals

- Aluminum

- Stainless Steel

- Alloy steel

- Tool steel

- Brass

- Copper

- Titanium

Plastics

- POM (Delrin/Acetal)

- PMMA (Acrylic)

- PEEK

- ABS

- Nylon (PA)

- PTFE (Teflon)

- PVC

- PEI (Ultem)

Secondary Machining Processes

If you require secondary machining or part finishing, we can accommodate your needs or requirements. Whether you require part finishing to increase visual appeal or need to improve the durability of a machined part, we can handle your part machining project from start to finish.

- As machined (Ra 3.2μm / Ra 126μin)

- Smooth machining (Ra 1.6μm / Ra 63μin)

- Fine machining (Ra 0.8μm / Ra 32μin)

- Polishing (Ra 0.8μm / Ra 32μin)

- Bead blasted

- Brushed + Anodized type II (Glossy)

- As machined + Anodized type II

- Chromate Conversion Coating

- Black oxide

- Electroless Nickel Plating

- Bead blasted + Anodized type II (Matte)

- Bead Blasted + Anodized type II (Glossy)

- Brushed + Electropolished (Ra 0.8μm / Ra 32μin)

- As machined + Anodized type III (Hardcoat)

- Brushed (Ra 1.2μm / Ra 47μin)

- Powder coated

What is CNC milling?

CNC milling (full name: Computer Numerical Control Milling) is a process that uses computer controls and rotating cutting tools to produce custom precision engineered parts or items. It is commonly associated with materials such as metal, plastic, and wood.

The process involves using these computer controls to operate machining tools to shape and cut materials to precise specifications to create custom precision engineered products. It is a very popular method because it can create fine sizes and shapes.

The machine receives instructions from a design that is input through a CAD program. The machine then mounts the correct tool and holds the material in place. Finally, the tool rotates at thousands of revolutions per minute and moves with the workpiece to contact different parts of the design.

Benefits and Features of CNC Milling

- High Precision and Accuracy: CNC milling machines are able to produce parts with extremely high precision and accuracy, which is critical to industries such as aerospace, medical, and automotive.

- Flexibility and Versatility: CNC milling machines can be programmed to produce a wide range of parts, from simple to complex designs. This flexibility enables manufacturers to produce custom parts to meet specific requirements.

- Create Angled Shapes: CNC milling is ideal for creating angular shapes, flat surfaces, grooves and channels, holes, curves, chamfers, and many other features.

- Cost Savings: CNC milling machines can provide significant cost savings. Increased efficiency and precision can reduce waste and scrap, while the ability to produce complex parts can eliminate the need for multiple machines or additional machining steps.

Differences between CNC Milling and CNC Turning

There are distinct differences between CNC milling and CNC turning. CNC milling uses a cutting tool that moves along a stationary workpiece to remove raw material. During CNC turning, the workpiece rotates while the cutting tool moves along the material to create the shape. CNC turning is suitable for projects that require cylindrical parts. CNC milling should be used for parts that do not require cylindrical shapes and can be used as a secondary finishing operation to add definition. Complex parts that require prismatic and cylindrical features can use a combination of milling and turning.

Industries We Serve

Whatever industry you belong to, we can meet your CNC milling needs. Our team of experts have many years of experience working closely with customers across a wide range of industries. This wealth of knowledge enables us to provide custom solutions that meet your specific requirements.

Aerospace

Automotive

Electronics

Industrial Equipment

Medical and Dental

Optics

Start your project today!

Our front-end business engineer staff will respond to your custom CNC machining parts within 30 minutes with one-to-one online service. You will get professional advice and save your R&D time.