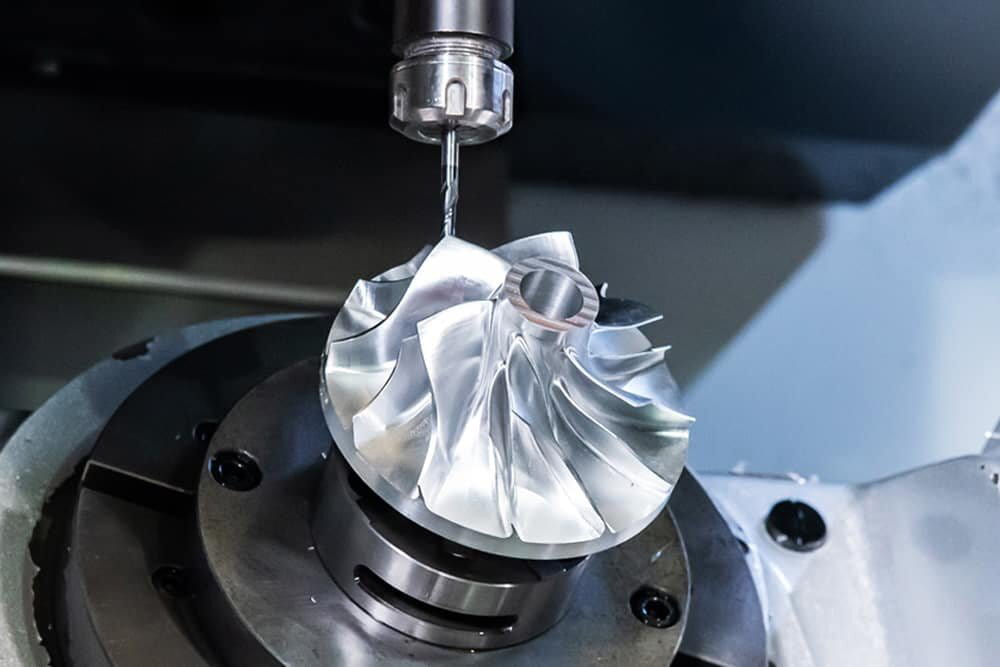

5 Axis CNC Machining

If you are looking for a high-precision, high-accuracy, and high-efficiency complex surface five-axis machining manufacturer, Xnparts can satisfy you, contact us immediately to get your manufacturing solution.

5-Axis CNC Machining Manufacturers

Xnparts’ 5-Axis CNC Machining services utilize the latest technologies and techniques to ensure that our customers receive precision engineering solutions that are exactly what they expect. 5-Axis Machining can meet and exceed complex challenges and technical specifications, resulting in increased production, reduced costs, and maintained accuracy and consistency. Our team of experienced engineers produces all of your precision components with a high degree of accuracy, no matter how complex they are. All of our manufacturing follows a built-in quality and control process, from the initial briefing and planning stages all the way through to delivery. This allows us to maintain a high level of quality and fast turnaround times for all of your products.

We are constantly on a path of development and improvement. Our team is constantly evolving in terms of technology and strategies to meet the needs of the ever-changing industry. By continuously developing solutions and alternatives, we enable our customers to survive in a competitive market. If required, we can meet your short-term production needs.

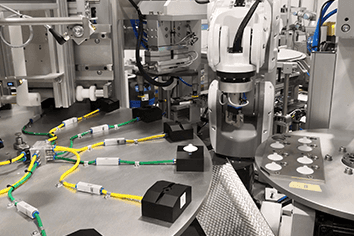

Equipped with the latest advanced equipment and measurement technology, we can provide a fully integrated service to deliver fully finished assembled components on time. This value-added capability supports our commitment to complete in-house management to maintain the highest quality and deliver finished components to reduce lead times.

5-Axis Machining Capabilities and Specifications

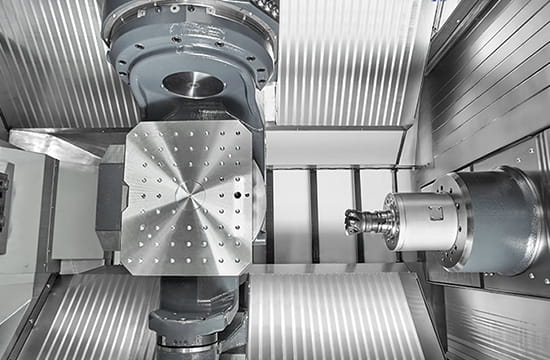

Xnparts’ 5-axis machining has a tight tolerance of +/- 0.005 mm, an angular tolerance of 1 degree (.002°), and can accommodate parts up to 1500 mm in diameter and 800 mm in height, with a table capacity of 1000 kg. X-axis travel is 800 mm, Y-axis travel is 1500 mm, Z-axis travel is 800 mm, and the universal table size is 1300 mm.

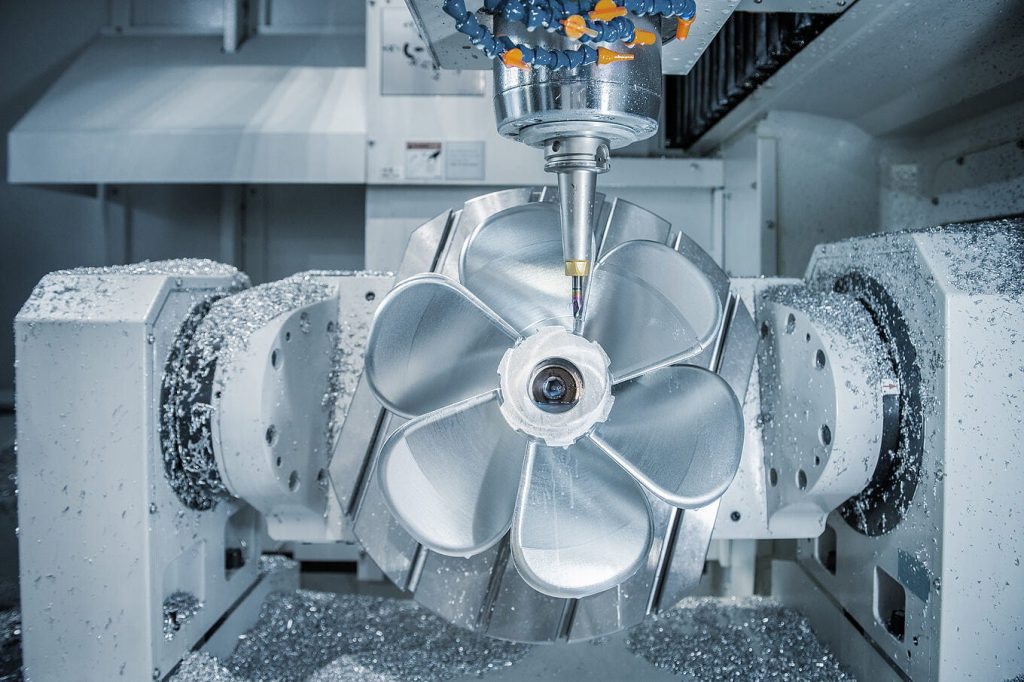

As long as you have a need for free-form surfaces, complex contours, whether the part is large, heavy, or small, Xnparts can help you achieve precision machining of parts with advanced equipment and professional and skilled machinists. Whether you need to produce large or small batches, you can produce on demand.

One-Stop Custom 5-Axis Machining Services

Other services we can provide you with throughout the manufacturing process include:

- Project Management: We provide design services, testing and guidance to our customers for the full product lifecycle or individual project management.

- Design and Development: Our team can research, design and develop parts and machine them, while focusing on safety, efficiency and case durability.

- Redesign for Efficiency: We can help you make simple changes to your design to maximize machining efficiency and reduce management expenses, while improving design quality and ensuring safety and reliability.

- CMM Inspection: During the part design, testing and manufacturing process, we can perform detailed inspections of your CAD models and 2D drawings to ensure that all components meet the required standards and are safe to use. We also offer Coordinate Measuring Machine (CMM) inspections, as with all our ancillary services, as a standalone service.

Start your 5-axis CNC machining project today

Whatever your application, Xnparts engineers are happy to help you get your product to market in the shortest possible time and at the lowest possible cost. We are committed to providing you with quality engineering, design services, and supply chain management to exceed your expectations and meet every specification.

5-Axis Machining Machine Types

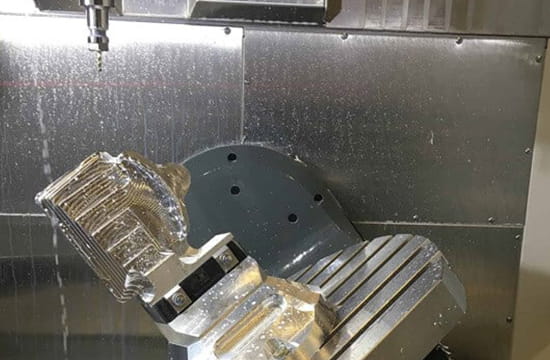

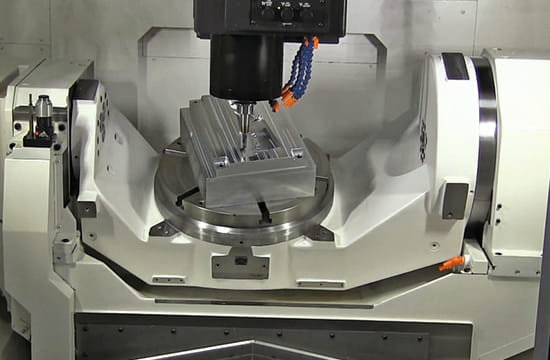

5-axis CNC machining has revolutionized the manufacturing process by enabling simultaneous movement along five axes. This advanced capability allows complex and precise components to be produced with unmatched efficiency. Our 5-axis machining machines are available in several different types.

5-Axis Simultaneous Machining

3+2 Axis Mahcining

Trunnion 5-Axis Machinining

Rotary 5-Axis Machinining

The tolerance standards we use

Our standard tolerances for custom CNC machining of metals are DIN-2768-1-m and for plastics are DIN-2768-1-c. Part geometry and material type have a significant impact on tolerances. For a case-by-case study, please contact us by email for details.

Quality Management

- Strict quality control process: IQC (Incoming Quality Control), FAI (First Article Inspection), IPQC (Input Process Quality Control), OQC (Outgoing Quality Control) and COC (Certificate of Conformity) can be provided according to your requirements.

- A wide range of testing methods and testing tools, such as pin gauges, colorimeter, etc.

- Various testing equipment: CMM, flash measuring machine, 3D scanner, 2D image measuring machine, etc.

- Highly skilled QA team with more than 10 years of experience.

- Strict quality control system to maintain process improvement and optimization.

- Material certificates and test reports can be provided upon request.

5-Axis CNC Machining Materials

We offer a wide variety of metal and plastic materials for 5-axis CNC machining. If you don’t see the material you need, please contact us or view our full materials list.

Metals

- Aluminum

- Alloy Steel

- Brass

- Bronze

- Copper

- Inconel

- Mild Steel

- Stainless Steel

- Titanium

Plastics

- ABS

- Delrin

- Nylon

- PC

- PEEK

- PEI

- PET

- PMMA

- PP

Surface treatment

We can perform surface treatment according to customer needs, and the methods we can provide are as follows.

- Anodized

- Polishing

- Nickel plating

- Zinc plating

- Brushing

- Laser engraving

- Oxide black

- Heat treatment

- Sandblasting

- Electrophoresis etc.

What is 5-axis machining and how does it work?

As a manufacturing and machining process, a multi-axis machine tool, specifically a 5-axis CNC machine, is a tool that is capable of manipulating a workpiece along multiple axes. These machines remove excess material from a workpiece during the milling process. In addition to the regular 3 axes (x, y, z), a 5-axis machine can also move the base along an additional fourth and fifth axis by rotating the spindle. Like any other CNC machine, a 5-axis CNC machine relies on computer instructions to control the movement of the cutting tool (and the workpiece) to produce the desired part. The 5-axis CNC machining process begins with a designer creating a 3D model of the desired part using a CAD tool (computer-aided design). The machinist then exports this CAD model to CAM (computer-aided manufacturing) software, which converts the drawing into a computer program (also known as G-code). The G-code contains a set of instructions that control the movement of the tool along the linear axes (X, Y, and Z) and the movement of the machine table along the rotary axes (A and C) to produce the desired part.

Benefits of 5-Axis CNC Machining

- Complex Geometries: Create complex shapes and contours that are impossible with 3-axis machining, opening up new design possibilities for your projects.

- High Efficiency: Reduce setup time and improve accuracy by machining multiple sides of a part in one operation to minimize human error and part handling.

- Superior Surface Finish: Reduce the need for post-processing by maintaining optimal tool-to-part contact, resulting in smoother surfaces and better details.

- Shorter Lead Times: Complete projects faster with fewer setups and tool changes, increasing productivity and reducing your product’s time to market.

- Economic Benefits of Small-Batch Production: Small batches or prototypes can be produced more economically, as reduced setup time makes it possible to shorten production cycles.

- Improved Precision: Consistently maintain tight tolerances on complex components to ensure precision at every design step.

5-axis machining vs. 3D printing

During 5-axis machining, the workpiece is often significantly altered. Experienced machinists program 5-axis CNC machines to produce finished parts from workpieces by instructing cutting tools to cut the workpiece.

In contrast, the 3D printing process is completely different, mainly through software programs to control the nozzle to automatically build the powdered substrate into the desired shape of the printed product in different ways. 3D printers have developed to the point where they can not only print plastics, but also use metal materials to manufacture products. However, because 3D printing can take a lot of time to complete, in most cases, this manufacturing process is not commercially comparable to traditional machining processes.

Aligning our business with our customers’ needs

It is critical to understand the drivers of our customers’ business. Our team of engineers takes the time to understand our customers’ primary goals and objectives and strives to align our business goals with what matters most to our customers. Customers can count on us to provide manufacturing solutions that not only help them complete their projects, but also save them time and money.

At Xnparts, our company always maintains a customer-centric service attitude. We often strive to understand our customers’ strategic direction. We strive to align our direction with the direction of our customers’ development. We believe that maintaining a continuous focus on our customers is the key to the success of Xnparts’ business.

Industries We Serve

We have been providing excellent on-demand 5-axis machining services to various industries around the world and continue to meet their diverse needs with optimized and flexible solutions. Here are some examples of industries that benefit from this technology:

Aerospace

Automotive

Electronics

Industrial Equipment

Medical and Dental

Optics

Send us your RFQ or project requirements and questions

Ready to experience the precision and quality of Xnparts manufacturing and 5-axis CNC machining services? Contact us today to discuss your project requirements or request a quote.