liquid silicone rubber molding

If you are looking for a proven design-to-injection molding manufacturing resource for your custom LSR injection molding project, our company can meet your needs. Advanced equipment and technology provide you with high-quality products to make your product ideas a reality.

Turnkey LSR Injection Molding Manufacturing Company

We want to save our customers valuable time and resources as much as possible, which is why Xnparts is a premium full-service injection molding service provider. We are happy to support you from your first product idea to the final manufactured product.

Our extensive service portfolio starts with an experienced team and state-of-the-art equipment that can meet your time and quantity requirements and ends with the production of silicone parts in our conventional manufacturing environment or cleanroom. Everything we do meets strict quality standards and is continuously monitored by our extensive quality management. In addition, right from the beginning, we actively involve our customers in the development process and develop customized solutions. The success of a project depends on the close cooperation between our experienced team and our customers. That is why we maintain open and transparent communication. We work hand in hand from the initial development phase, taking all aspects into consideration. This results in innovative and efficient molds of the highest quality. Our commitment does not end with the completion of the mold. We accompany our customers throughout the life cycle of the project and provide advice at any time. This long-term support is an important part of our service. At Xnparts, we rely on partnership and teamwork to develop the best solutions with our customers and ensure sustainable cooperation.

We’ll help you avoid and mitigate major risks in your LSR projects

We’ll work with you early in the project to help you consider quality and certification, avoiding rework that adds cost and delays. Count on us to:

- Consult with you on prototypes, considering long-term production engineering needs.

- Help you consider all material options before moving to the next phase of your project.

- Review with you key functional features, such as parting lines and gate locations.

- Help you develop specifications to ensure they are not overly restrictive.

One-stop silicone and rubber injection molding service provider

We continue to expand our technology and expertise to provide accurate, reliable, high-quality, high-volume LSR components. Our technology, services and molding expertise provide value-added turnkey LSR solutions for our customers.

Design & Prototype Services

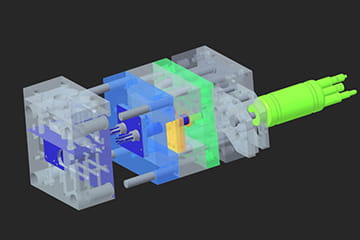

Mold Design & Fabrication

Rigorous Material Selection

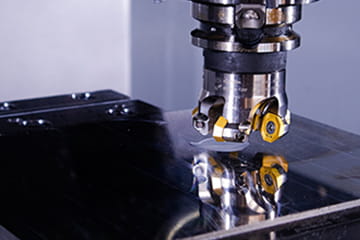

CNC Machining

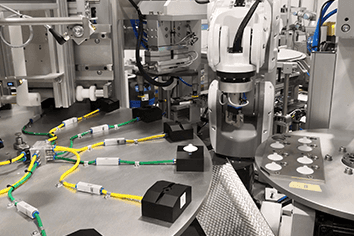

Cleanroom Medical Molding Methods

Secondary Processing

Quality Inspection and Finishing Options

Depending on your application requirements, you can choose from the following when requesting a quote for your silicone rubber product.

- Quality inspection for production orders available on request

- Design for Manufacturability (DFM) feedback

- Scientific molding process development reports

- In-process coordinate measuring machine (CMM) inspection and machine monitoring

Do you have a silicone product project to discuss? Contact us today for a free quote!

Liquid Silicone Rubber Injection Molding Capabilities

As a leading silicone mold manufacturer, Xnparts is able to provide fast, high-quality service that prioritizes customer satisfaction in custom silicone molding projects. Our team of LSR injection molding experts excels in providing a comprehensive service, from prototyping to mass production of high-precision components.

Liquid Silicone and Rubber Overmolding

To reduce costs, improve the quality of your products, and extend their lifespan, we utilize liquid silicone and rubber overmolding. Medical products need to consider biocompatibility, and therefore, we use silicone overmolding to produce a variety of medical devices.

Silicone Micromolding

We use silicone micromolding technology, the latest trend in LSR manufacturing, to produce small, high-precision and precision parts. As parts get smaller, we strive to provide our customers with incredible accuracy and precision in all our LSR products.

LSR Compression Molding

Our team of experts utilizes this highly sophisticated molding technology to produce composite components in large quantities. The LSR compression molding process involves low tooling costs. This is best suited for manufacturing large items and thicker parts, and is cost-effective for short-run production runs.

Silicone Prototypes

Whatever the product, we create silicone prototypes with a lot of patience and experience. We understand that without a prototype, it is extremely difficult to move forward. That is why we provide silicone prototypes to verify that your design will function as expected.

Silicone Insert Molding

At Xnparts, the silicone insert molding products and technologies we use are the molding of silicone through a substrate to produce the final part. By combining the advantages of both materials, the process supports variations in hardness and stiffness.

What is Liquid Silicone Rubber Injection Molding?

Liquid Silicone Rubber (LSR) injection molding or Liquid Injection Molding (LIM) is a thermosetting process that produces a large number of flexible, durable, complex and precise silicone rubber parts. The process begins by mixing two compounds (usually consisting of a base molding silicone and a platinum catalyst). The mixture is then injected into a mold and heat cured to create a flexible silicone part. It is important to note that the two compounds need to be mixed in an intensive distribution while being kept at a low temperature before being pushed into a heated cavity and heat cured. The liquid silicone rubber is cured by heating to produce a solid part or product.

Disadvantages of Liquid Silicone Rubber

- LSR cannot be reshaped once cured, so LSR cannot be recycled

- Long production time and high cost

- If not treated, they feel sticky, attracting dust and other particles

- They are not suitable for immersion applications in alcohol or gasoline

- LSR inhibits cure when exposed to certain materials (such as sulfur and latex)

- Limited material selection for LIM process

- Limited grades of silicone available

Design and Prototype LSRs with Manufacturing in Mind

We work with you early in the project to focus on quality and better understand the design input and output requirements of your custom part. Giving us a better understanding of the design intent of your product will make the product launch smoother and significantly reduce future risks. Questions include:

- Do you need an early prototype or a manufacturing-quality replica prototype?

- How many cavities does the tool need to support the volume required for development?

- Where are your critical sealing surfaces and functional areas?

- Where can we place gates and parting lines?

- What are the general operating conditions such as temperature, fluid contact, cycle rate, etc.?

Alternatives

From a process point of view, the closest alternative is the injection molding of thermoplastic elastomers (TPE) or thermoplastic vulcanizates (TPV): these are flexible, impact-resistant plastics that are melted, injected and cured like other thermoplastics. The advantage of these materials is that they do not require metering and mixing. However, despite their elastomeric properties, TPEs and TPVs have the weaknesses of thermoplastics, such as degradation in sunlight, and may not be suitable for some medical applications.

In addition to injection molding, TPE is one of the few materials that can be made into flexible 3D printing filaments: this material is used in the additive manufacturing of rubber-like parts. TPU is another such material.

Industries We Serve

Whatever the industry, our liquid injection molding units are capable of producing liquid silicone rubber parts or components that must withstand extreme conditions and make your product more effective. Industries and applications include:

Aerospace

Automotive

Electronics

Industrial Equipment

Medical and Dental

Optics

Contact us today to discuss your project

With design flexibility, advanced technology and superior quality, Xnparts is your best partner for high-volume production of liquid silicone components. Contact us today to discuss your requirements.