3D Printing

Reduce time to market, accelerate product development, and improve manufacturing with true industrial-scale additive manufacturing. Contact us today.

Advanced 3D Printing Additive Manufacturing Company

Xnparts is an advanced processing, manufacturing and assembly factory. We specialize in advanced manufacturing technology and always focus on excellence. We provide services from concept to completed mass production.

Our technical expertise, strict manufacturing standards and quality control are enhanced and balanced by creativity, insight and vision. Our willingness to accept challenging projects and difficult applications is what makes us different.

Xnparts has advanced facilities and a full range of advanced manufacturing equipment including precision multi-axis CNC machining centers and plastic and metal additive manufacturing systems, which enables us to manufacture the most challenging multi-disciplinary advanced manufacturing projects. In addition, our team of engineers has extensive experience, and our team is committed to solving the most technically challenging and demanding manufacturing applications.

Our goal is not just to meet market needs, but to drive market development. We use the latest design, simulation and manufacturing software and hardware to achieve this goal. We also employ engineering and scientific talents to provide cutting-edge capabilities in gas and heat distribution, building complex internal structures, and developing new materials and processes for additive manufacturing applications.

We specialize in manufacturing technically difficult and complex components and systems for global industrial and technology leaders. We achieve this by focusing on providing the highest levels of quality and customer service in the industry. We build strong connections with our customers and work with them to make new products and improved processes a reality.

Our Philosophy

We want to make the world a better place through technology, and we believe custom 3D printing is one way to do that. When anyone can make completely unique physical objects at an affordable price, without the money or technical skills to own and operate their own 3D printer, a whole new creative energy will be unleashed around the world. We created Xnparts in the hope that it will be a positive force for startups, DIY enthusiasts, and creative spirits around the world.

We make your 3D printed product design unlimited

Our concepts are able to maintain their individuality in the ever-changing rapid prototyping and manufacturing industry.

We have a full team of professional engineers and designers who will work with you to verify your design, tolerances and more. We take the time to understand your business needs, which means we ask the right questions to ensure we are manufacturing the right part with the right end goal in mind.

Whether you are assembling fit and function test models, small batch production or mass production of 3D printed parts, we can help. We have worked with manufacturers in many industries and are familiar with the different requirements of these different fields and the regulations and requirements that come with them.

We work with you throughout the manufacturing process and provide professional advice when necessary. Whether you are looking for a low-cost solution without sacrificing quality, or are stuck in the early planning stages, we can guide you from concept to production.

Your partner for additive manufacturing design and manufacturing

Whether it’s rapid prototyping or manufacturing 3D parts, we can meet your needs and provide the highest quality parts at a competitive price.

One-Stop 3D Printing Solutions

Xnparts’ professional 3D printing services ensure an effective turnkey solution for precision products and detailed designs. Our team is experienced in using a wide range of materials and multiple 3D printing technologies, working closely with customers to select the best combination of materials and production methods to deliver high-quality results and optimal versatility while helping you reduce turnaround time. Whether it’s an initial prototype or an end-use part, we leverage cost-effective 3D printing to transform the way new products are brought to market.

3D Scanning

Using cutting-edge 3D scanning technology, the Xnparts team provides a fast and seamless way to acquire fully parametric and modifiable CAD designs.

Design & Prototyping

Maximize the potential of additive manufacturing with our design and prototyping solutions. We’ll help you at every stage, from concept to full implementation and production.

Custom Parts

From single prototypes to large end-use components, we deliver exceptional on-demand additive manufacturing. Experience fast turnaround with parts produced to fit your schedule in as little as 24 hours.

3D Printing Technologies We Use

We offer the industry’s most comprehensive range of metal and plastic 3D printing technologies for any application, small or large, simple or complex, prototype or production. Our experts work closely with your team on everything from identifying and evaluating 3D printing candidates to exploring design improvements and cost savings.

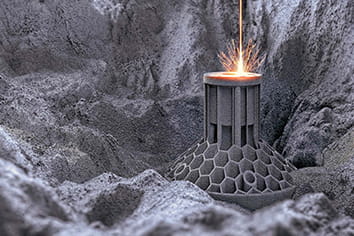

Metal 3D Printing

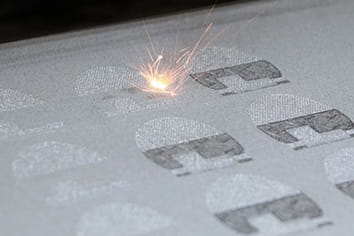

Selective Laser Sintering (SLS)

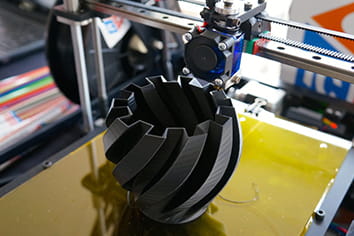

Fused Deposition Modeling (FDM)

Multi Jet Fusion (MJF)

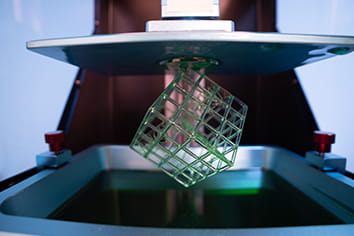

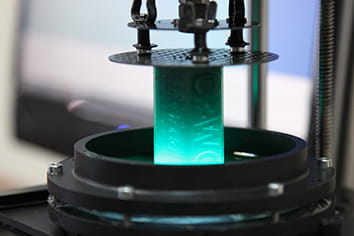

Stereolithography (SLA)

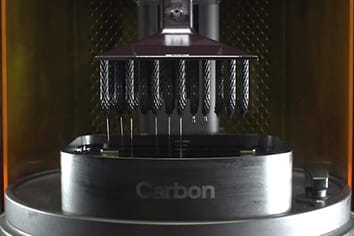

Carbon Digital Light Synthesis (DLS)

Polyjet

Direct Metal Laser Sintering (DMLS)

Metal Binder Jetting (MBJ)

Silicone 3D Printing

DLP

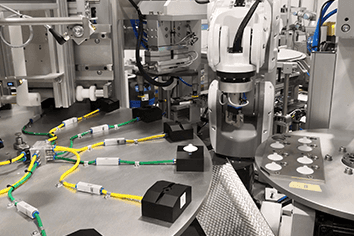

Cleanroom Certification

Xnparts has built a state-of-the-art cleanroom for its additive manufacturing operations, allowing for the handling of sensitive and/or mission-critical materials and components in a cleanroom environment. The cleanroom houses additive manufacturing equipment and materials, including multiple production-proprietary thermoplastic machines that are capable of running 24/7 and can be remotely monitored from anywhere in the world. Applications range from R&D prototypes to production-ready parts for medical use, including human body devices.

High-quality, production-ready parts

Ready to take advantage of the many benefits of 3D printing? With the wide range of printing technologies available at Xnparts, we can help you develop the high-quality parts you need faster than ever before. Whether you’re tired of supply chain bottlenecks, slow product development, or the high costs associated with traditional tooling methods, 3D printing can help. Our additive team has extensive engineering and manufacturing knowledge to help you narrow down the methods, materials, and post-processing options that are right for your application.

Get a Free Project Review

Xnparts’ 3D printing services are customized to the needs of modern manufacturing, providing a comprehensive solution for the efficient production of detailed, complex and multi-material products.

Material Options

We offer thousands of material options, including strong thermoplastics, biocompatible materials, rigid materials, rubbers, full colors, and metals. Choosing the right material is critical. With our in-house additive manufacturing technology, we can offer a dynamic range of materials to meet a variety of application needs throughout your product development lifecycle. With a wide range of options, we can meet the critical needs of manufacturers and product development teams who are time and cost sensitive, while still achieving complex geometries and the benefits of using additive processes. From rapid concept modeling to highly detailed, ultra-realistic end-use parts, we have the material solutions to usher in a new generation of products and parts.

Surface treatment options

- Unfinished

- Natural

- Standard

- Clear Coat

- Painting

- Plating

- Dyeing

- Decaling

- Polishing

- Heat Treatment

- Machining

- Custom

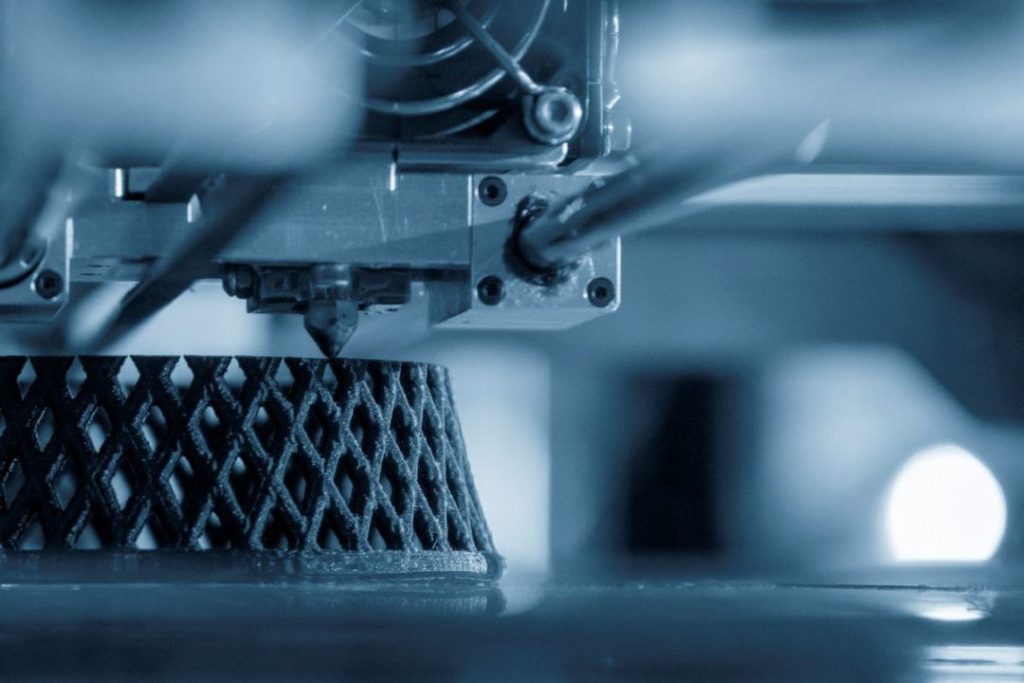

What is 3D printing?

3D printing or additive manufacturing (AM) creates three-dimensional parts based on a computer-aided design (CAD) model by adding material layer by layer until a physical part is created. 3D printing is a manufacturing process where material is laid down layer by layer to form a three-dimensional object. It is an additive process because the object is built from scratch, rather than a subtractive process where the material is cut, drilled, milled or machined. The technology has evolved to the point where a variety of materials, including plastics or metals, can be printed with 3D printers. All it takes is a digital file containing the three-dimensional data, whether created with a computer-aided design (CAD) or computer-aided manufacturing (CAM) program, or with a 3D scanner, to be transformed into a physical object.

What are the advantages of 3D printing

The main advantage of 3D printing over traditional manufacturing methods is low cost. 3D printing can also significantly reduce the number of parts sent to production and then returned, thereby reducing a company’s carbon footprint.

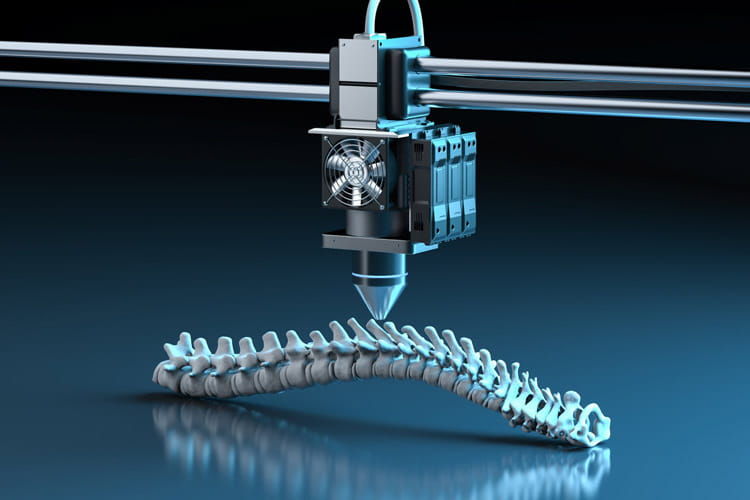

In addition, 3D printing has high detail resolution and high strength, making it ideal for functional prototypes and end-use parts in all industries, including aerospace and automotive engineering. If a part is defective, manufacturers can simply print another part using a 3D printer without the need for additional tooling. In addition, changes to 3D printed parts can be made without creating new molds

Since each part is made individually and only after it is ordered, 3D printing can accurately match orders to the quantity required for the finished part. This 3D printing capability allows manufacturers to get closer to ideal production levels while minimizing excess inventory.

3D printing offers fast turnaround times and high-quality prints. In short, it depends on the product specifications, the materials used, and the complexity of the components involved. The turnaround time for most projects depends on your project requirements.

Industries We Serve

We have a full team of professional engineers and project managers who will work with you to validate your CAD designs, product functionality, dimensional tolerances, and more. As a professional prototype manufacturer, we have a deep understanding of the prototyping and production needs of any business. We strive to meet all specified timelines and provide quality-assured products at affordable prices to customers around the world.

Aerospace

Automotive

Electronics

Industrial Equipment

Medical and Dental

Optics

Ready to start making custom 3D printed parts?

Whether you’re creating a one-off prototype or a low-volume production run, we’ve got you covered. From complex projects developed with our team to parts you print online at your own speed, we can help you in the way that works best for you.