Rapid Prototyping

If you are developing a new product or improving an existing one, rapid prototyping is ideal for testing, iterating, and tweaking concepts. It is a way to speed up your design process and get your ideas and products to market faster. Do you need parts as quickly as possible to validate your project? Contact us today.

Rapid Prototyping Company

Xnparts uses proven rapid prototyping technology to bring your designs to life. We offer a full range of rapid prototyping services, providing customers with a range of integrated development solutions. Our team of skilled experts can quickly produce models, prototypes, and profiles without compromising quality. As a result, engineers, manufacturers, and designers can evaluate new products quickly and cost-effectively. Our rapid prototyping services allow you to evaluate products with less risk.

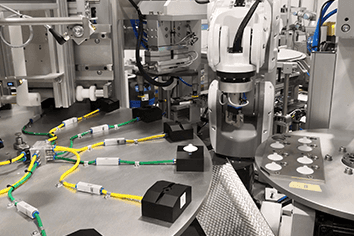

For rapid prototyping services, our team uses innovative tools and has the expertise needed to ensure success. As a result, the Xnparts team can execute projects quickly and efficiently. In addition, our company’s investment in advanced equipment and cutting-edge technology and experienced team of engineers, our rapid prototyping services can achieve excellent precision and fast turnaround. What’s more, in-house advanced testing equipment can verify the accuracy of parts in minutes and is able to generate inspection reports to meet any project requirements. Whether it is CNC machining, 3D printing or other manufacturing methods, we can provide customers with high-quality manufacturing services and are committed to providing excellent service and product quality.

Get the Right Prototype for Your Needs

Not all rapid prototyping companies are created equal. At Xnparts, we will not only build your prototype, but we will help you evaluate the goals of your prototype so that we can create the perfect prototype product for your unique needs. Our team of product designers and engineers will help you evaluate features, functionality, and prototype process options to ensure we can maximize the value and minimize the cost of your prototype.

So whether you want a prototype to show investors or clients, a look-alike mockup for marketing photos, or a fully functional prototype for validation testing, we can work with you to design and build the perfect prototype.

Rapid prototyping services make your design a reality quickly

In today’s fast-paced market, companies often face time consumption, cost inefficiency and inconsistent quality when producing complex parts. These challenges can become a significant barrier to innovation and market response, especially in high-tech industries such as aerospace, automotive and robotics. Xnparts has a deep understanding of this problem. Therefore, our advanced rapid prototyping services use the most advanced 3D rapid prototyping technology to help customers quickly turn their designs into reality in a short period of time, providing accurate and high-quality products from the beginning.

Our rapid prototyping process can be designed to alleviate common manufacturing obstacles. By quickly creating accurate prototype parts, customer companies can test and improve their designs without the high costs and time delays of traditional methods. This means that iterations can be carried out quickly and efficiently, bringing your products to market faster.

Start your project now

When you send us your 3D CAD file, our technicians will evaluate your requirements and suggest the best combination of services to meet your expectations.

One-stop rapid prototyping service

Xnparts provides a full range of manufacturing services and solutions for your prototype or production needs. From concept to creation, your ideas and designs are safely and efficiently produced under the same roof. We ensure that the final product we produce is a perfect match with your original ideas and designs. No matter the size of the project, from prototype orders to small batch production of thousands, we are your reliable source for quality manufacturing.

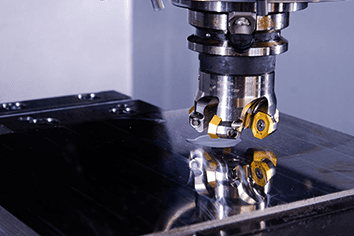

CNC Machining

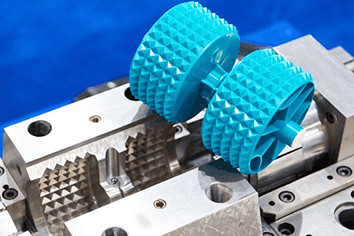

Plastic Injection Molding

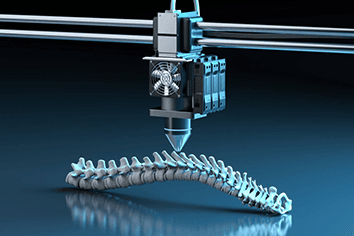

3D Printing

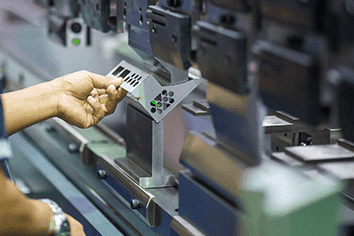

Sheet Metal Fabrication

Vacuum Casting

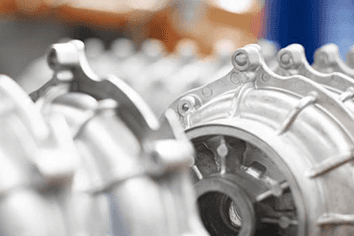

Die Casting

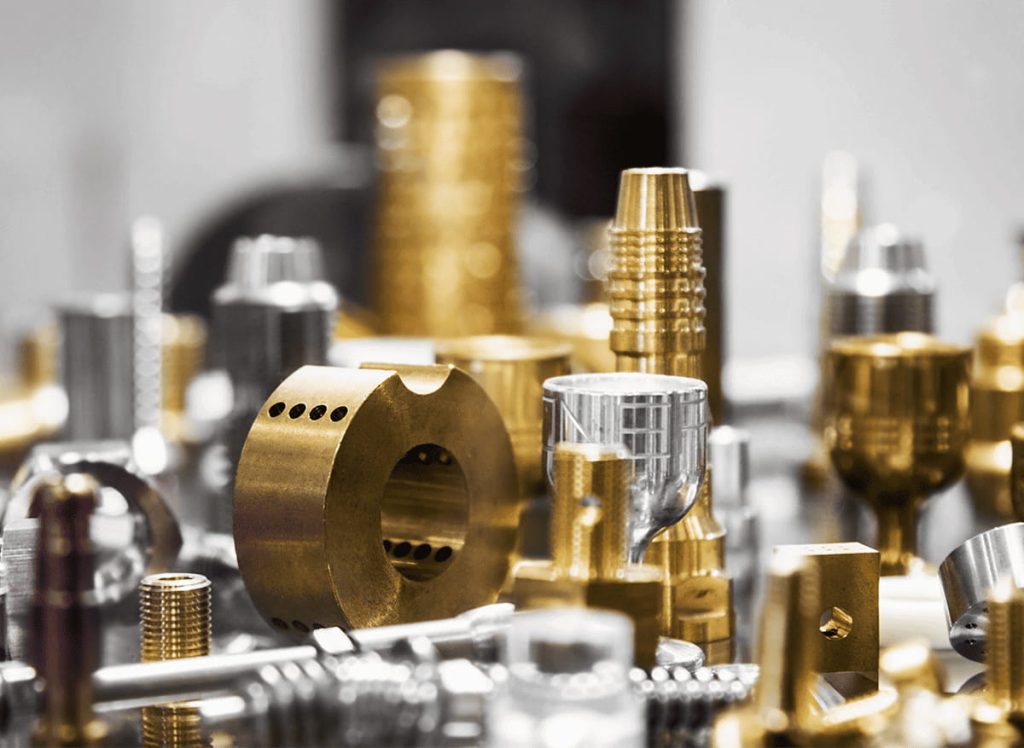

Various Materials for Rapid Prototyping

Plastics, metals, and silicone can all be used to make prototypes. It is important to choose the right material for your design. If the material you want is not listed below, please contact us to purchase it.

Various types of plastics

- ABS

- Nylon (PA)

- Polycarbonate

- Polypropylene

- HDPE

- Acetyl (POM)

- Noryl

- PMMA (Acrylic)

Various types of Metals

- Aluminium

- Steel

- Stainless Steel

- Brass

- Copper

- Magnesium

- Titanium

- Zamak

Custom rapid prototype surface finishing

After rapid prototyping is completed, most parts need to be surface treated. The purpose of surface treatment is to meet the corrosion resistance, wear resistance, decoration or other special functional requirements of the product.

Common surface treatment processes include grinding, polishing, electroplating, anodizing, black passivation, wire drawing, sandblasting, painting, powder spraying, printing (silk screen printing, pad printing), laser engraving, phosphating, etc.

Why do you need customized rapid prototyping services?

- Rapid prototyping services can reduce the manufacturing time of product models or molds, helping you significantly shorten the development time of new products;

- Rapid prototyping design and manufacturing services will improve the design and production capabilities of complex parts, making the manufacturing of complex models easy and possible;

- Customized prototyping services can quickly achieve single-piece and small-batch production, and bring new products to the market in advance.

- During the rapid prototyping process, product mold design errors can be discovered in time, errors can be discovered and modified early, and large losses caused by subsequent process changes can be avoided;

- Rapid prototyping services support synchronous project implementation, so that new product design, product evaluation, product sample manufacturing, production preparation, etc. can be carried out simultaneously;

- Rapid prototyping and manufacturing services can greatly reduce the cost of product development, design and manufacturing.

What is Rapid Prototyping?

Rapid prototyping is a technique for quickly manufacturing physical parts or components based on a 3D design. With rapid prototyping, engineers and designers can create better end products, iterate multiple times between digital designs and physical prototypes, and have a fast and cost-effective workflow.

Rapid prototyping is a common first step in the product development cycle that allows for the rapid prototyping of initial designs. At this stage in the development process, the team focuses on the functionality of the product or component being created. These prototypes will contain the basic functionality needed for testing and gathering feedback. The speed at which these prototypes are created is highly valued, which means that fast turnaround processes such as 3D printing or CNC machining are recommended.

How to choose the right prototyping technology?

Typically, the appropriate choice of rapid prototyping method depends on various factors, including time cycle, part specifications and complexity, expected budget, application and functional requirements. Elaborate, complex design prototypes always cost more because they require more operating time, skilled personnel and power consumption. Therefore, it is necessary to seek help from a reputable prototype manufacturing service provider and choose the right process. They can help you make a reasonable choice within a limited budget.

For more detailed prototypes, product designers usually adopt 3D printing and CNC machining because they can meet strict part dimensions or tolerances. For simple prototyping, injection molding may be the best choice. In addition, injection molding is economical for high-volume production when you need to manufacture a prototype in a limited time.

Industries We Serve

Xnparts provides high-quality, fast tooling and prototyping services to markets around the world. Whatever product you need, from toys to auto parts to electronics, we can help you make it a reality at the best price and as fast as possible. As long as you have an idea, please feel free to contact us and talk to our friendly engineers, we can make your business a success.

Aerospace

Automotive

Electronics

Industrial Equipment

Medical and Dental

Optics

Need a quote for a custom rapid prototype?

You can get custom and timely rapid prototype quotes in different materials and quantities from Xnparts to reduce your product development costs. Our engineers can help you with your rapid prototype product requirements and answer any questions.